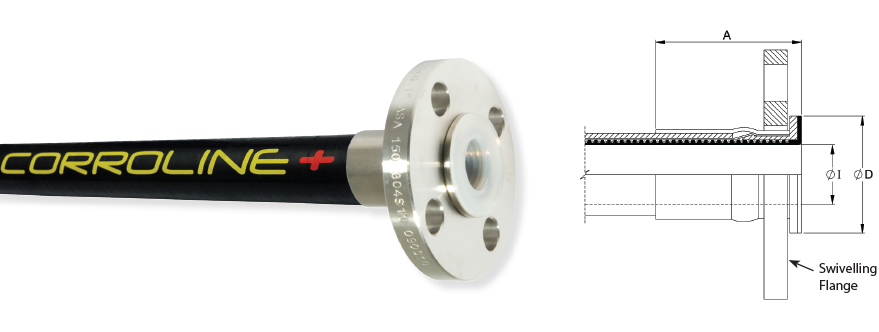

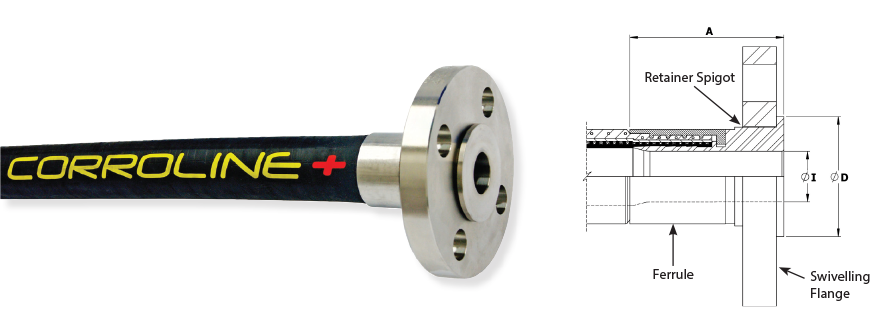

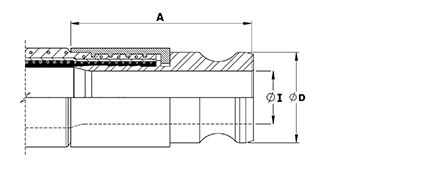

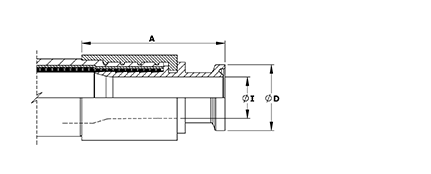

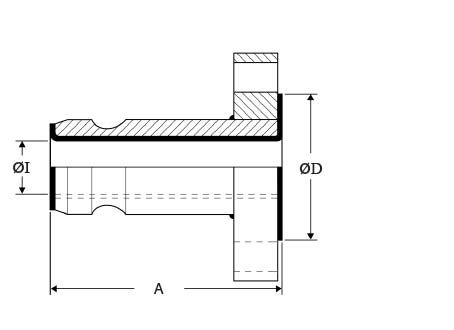

Corroline+ Non-Lined Swivel Flange Fittings

End Fitting Specifications

- ANSI B16.5 (also ASME B16.5) Class 150# and 300#

- DIN PN10, PN16 and PN40*

- JIS 10K

- Other Pressure Ratings and Flange Specifications are also available.

*DIN PN10, PN16 and PN40 Flanges all have the same dimensions, and so are fully interchangeable

Temperature and Pressure Ratings

- ANSI 150# = 16 Bar (230 psi), ANSI 300# = 41.4 Bar (600 psi)

- DIN PN10 = 10 Bar (145 psi), DIN PN16 = 16 Bar (230 psi)

- DIN PN40 = 40 Bar (580 psi)

End Fitting Materials

- Flanges normally in Grade 304 SS, or Grade 316 SS if required

- Flange Retainers in Grade 316L SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316 SS

Alternative Options for Flange Component only:

- Zinc Plated Carbon Steel

- Grade 316 SS

Surface Finish:

- All surface finishes are to ASME BPE-SF-O (No finish required).

- If a specified finish on a particular surface is required, please state on the enquiry and order.

|

| Nominal Hose Size |

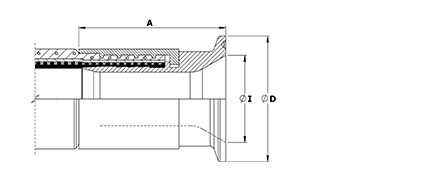

*Fitting Length A

ASA150 |

Flared Diameter D

ASA150 |

Fitting Inside Diameter I

ASA150 |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

1.67 |

42.50 |

1.38 |

35.00 |

0.37 |

9.40 |

0.57 |

1.25 |

| 3/4 |

20 |

1.86 |

47.24 |

1.69 |

42.90 |

0.62 |

15.75 |

0.84 |

1.84 |

| 1 |

25 |

2.36 |

60.00 |

2.00 |

50.80 |

0.85 |

21.50 |

1.20 |

2.63 |

| 1 1/4 |

32 |

2.67 |

67.72 |

2.50 |

63.50 |

1.03 |

26.21 |

1.59 |

3.50 |

| 1 1/2 |

40 |

2.75 |

69.86 |

2.87 |

73.00 |

1.25 |

31.75 |

2.15 |

4.73 |

| 2 |

50 |

3.20 |

81.22 |

3.62 |

92.00 |

1.76 |

44.60 |

2.92 |

6.41 |

| 21/2 |

65 |

3.70 |

94.00 |

4.13 |

105.00 |

2.25 |

57.15 |

4.36 |

9.59 |

| 3 |

80 |

3.74 |

95.00 |

5.00 |

127.00 |

2.63 |

66.7 |

6.02 |

13.24 |

| Nominal Hose Size |

*Fitting Length A

PN10/16 |

Flared Diameter D

PN10/16 |

Fitting Inside Diameter I

PN10/16 |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

1.79 |

45.50 |

1.77 |

45.00 |

0.37 |

9.40 |

0.78 |

1.72 |

| 3/4 |

20 |

2.11 |

53.50 |

2.28 |

58.00 |

0.62 |

15.75 |

1.12 |

2.47 |

| 1 |

25 |

2.44 |

62.00 |

2.68 |

68.00 |

1.12 |

28.50 |

1.43 |

3.15 |

| 1 1/4 |

32 |

2.70 |

68.50 |

3.07 |

78.00 |

1.03 |

26.21 |

2.35 |

5.17 |

| 1 1/2 |

40 |

2.91 |

74.00 |

3.49 |

88.00 |

1.70 |

43.10 |

2.76 |

6.06 |

| 2 |

50 |

3.50 |

89.00 |

4.02 |

102.00 |

2.15 |

54.50 |

3.62 |

7.96 |

| 21/2 |

65 |

3.62 |

92.00 |

4.80 |

122.00 |

2.25 |

57.15 |

4.58 |

10.07 |

| 3 |

80 |

3.74 |

95.00 |

5.43 |

138.00 |

2.63 |

66.70 |

6.03 |

13.26 |

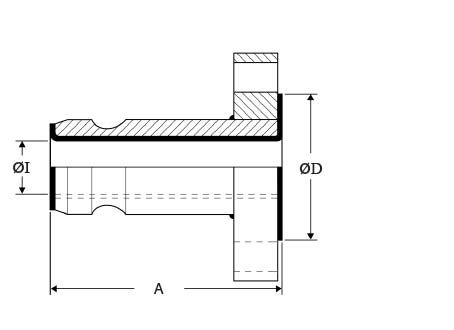

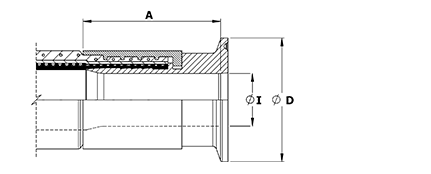

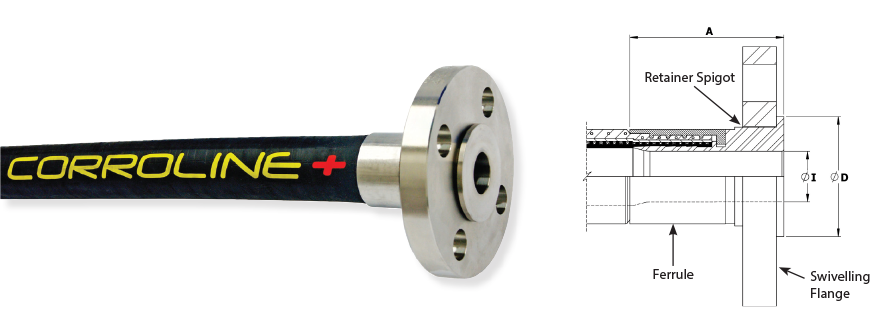

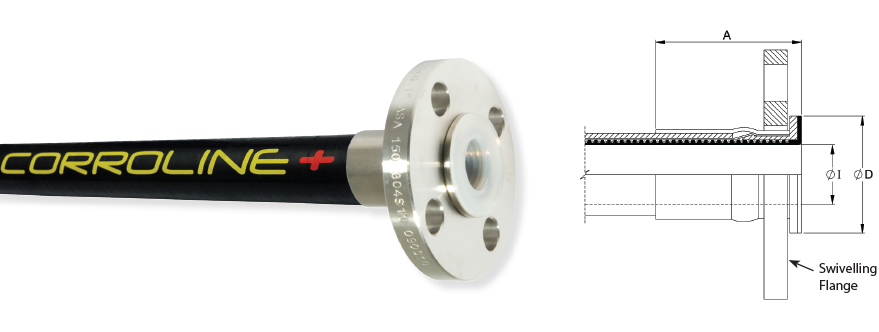

Corroline+ PTFE Lined Fittings

Integral PTFE Lined Flange Fittings

Flange Specifications

- ANSI B16.5 (also ASME B16.5) Class 150# and 300#

- *DIN PN10, PN16 and PN40

- JIS 10K

- Other Pressure Ratings and Flange Specifications are also available.

*DIN PN10, PN16 and PN40 Flanges all have the same dimensions, and so are fully interchangeable

Maximum Pressure Ratings for Flange Fittings

- ANSI 150# = 16 Bar (230 psi), ANSI 300# = 41.4 Bar (600 psi)

- DIN PN10 = 10 Bar (145 psi), DIN PN16 = 16 Bar (230 psi)

End Fitting Materials

- Flanges in Grade 304 SS

- Flange Retainers in Grade 316L SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316 SS

Alternative Options for Flange Component only:

- Zinc Plated Carbon Steel

- Grade 316SS

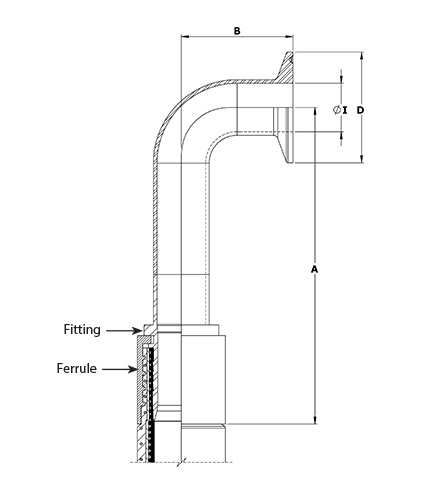

90° Elbow Flange Fittings

- 90˚ Elbow Integral PTFE lined Flange Fittings are available for sizes 1”, 11/2” and 2” - Consult Aflex Hose for details.

| Nominal Hose Size |

*Fitting Length A

ASA |

*Fitting Length A

PN |

Flared Diameter D |

Fitting Inside Dia. & Hose Bore I |

Recommended Bolt Tightening Torques |

Weight of Fitting |

| ASA 150# |

*DIN PN10/16/40 |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

ft.lbs |

mtr.kgs |

Kg |

Lbs |

| 1/2 |

13 |

2.24 |

57.0 |

2.28 |

58 |

1.25 |

32 |

1.25 |

32 |

1/2 |

13.2 |

8 |

1.10 |

0.54 |

1.20 |

| 3/4 |

20 |

1.89 |

48.0 |

1.93 |

49 |

1.69 |

43 |

1.97 |

50 |

3/4 |

19.4 |

8 |

1.10 |

0.88 |

1.90 |

| 1 |

25 |

2.40 |

61.0 |

2.48 |

63 |

2.00 |

50 |

2.50 |

63 |

1 |

25.2 |

10 |

1.40 |

0.96 |

2.10 |

| 11/4 |

32 |

2.24 |

57.0 |

2.32 |

59 |

2.48 |

63 |

3.10 |

78 |

11/4 |

32.0 |

12 |

1.66 |

1.15 |

2.53 |

| 11/2 |

40 |

2.36 |

60.0 |

2.44 |

62 |

2.875 |

73 |

3.50 |

88 |

11/2 |

38.6 |

15 |

2.10 |

1.75 |

3.80 |

| 2 |

50 |

2.72 |

69.0 |

2.91 |

74 |

3.625 |

92 |

4.00 |

102 |

2 |

51.2 |

25 |

3.50 |

2.70 |

5.95 |

| 21/2 |

65 |

4.86 |

123.5 |

4.86 |

123.5 |

4.13 |

105 |

4.80 |

122 |

21/2 |

63.7 |

30 |

40.18 |

4.21 |

9.26 |

| 3 |

80 |

5.17 |

131.4 |

5.17 |

131.4 |

5.00 |

127 |

5.00 |

127 |

3 |

76.8 |

40 |

53.94 |

4.75 |

10.44 |

*The listed Flare Diameters for 1/2”, 3/4” and 1” DIN PN10/16/40 are not all full size due to limitations on PTFE flare diameters

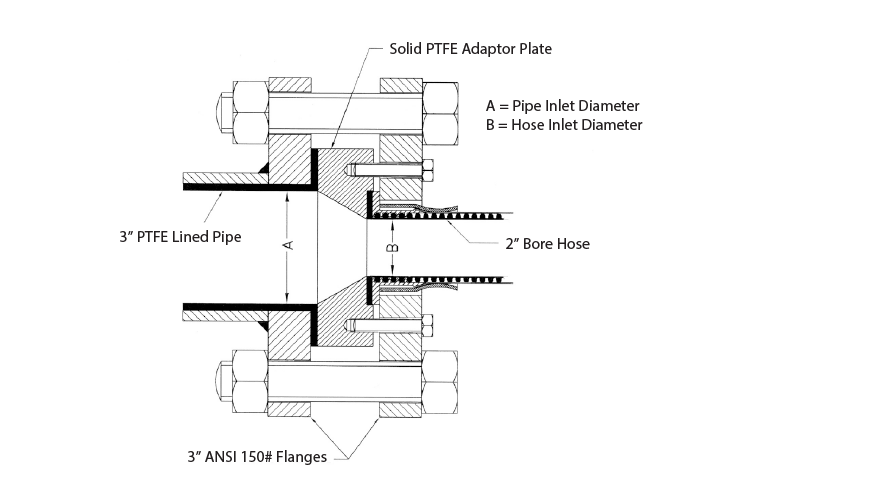

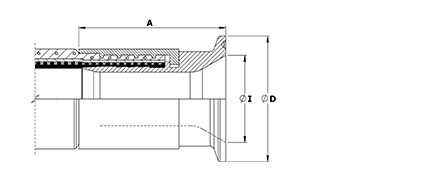

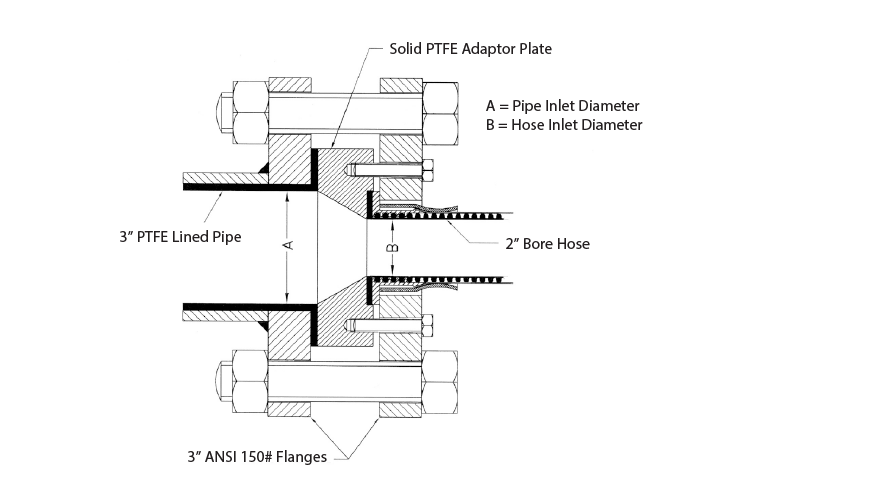

‘Step-Up’ PTFE Lined Flange Fitting Design for Corroline+ Hose

Because Corroline+ Hose has better flow rates than some larger bore sizes of Convoluted PTFE hose, it represents a superior alternative when fitted with the larger size flanges in some applications.

It is, however, necessary to also “Step-Up” the PTFE-lined bore, to ensure a diameter match with the mating connector.

This is best achieved using a solid PTFE Adaptor Plate, as shown in the drawing.

Example: a 2” hose to 3” ANSI 150# PTFE Lined Flange Joint

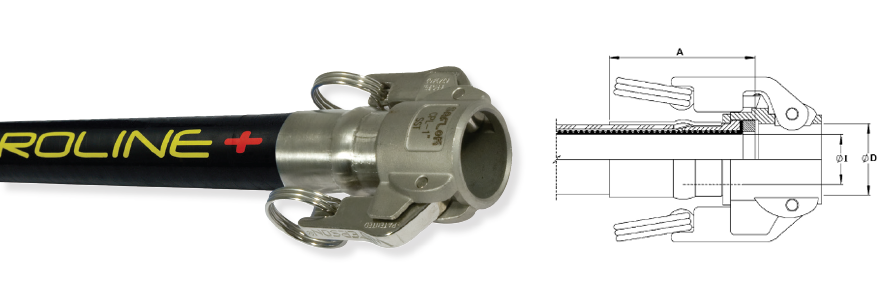

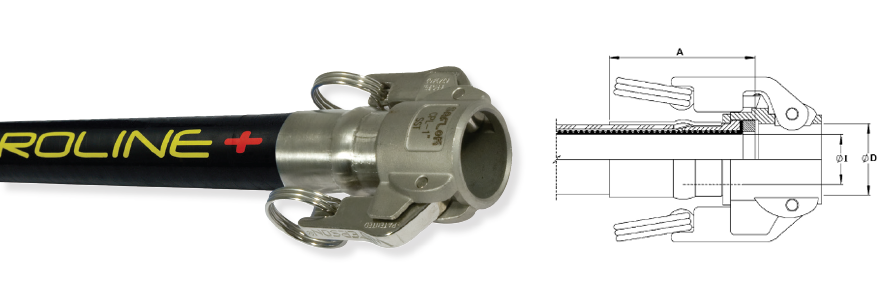

Corroline+ Female Cam & Groove Fittings PTFE Lined & Non-Lined

End Fitting Specifications

- Generally in accordance with A-A-59326 (replaces MIL-C-27487) and EN14420-1 (replaces DIN 2828), and all are fully interchangeable.

End Fitting Materials

- Spigot in Grade 316L SS

- Body in Grade 316C SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

- Standard Gasket is Buna N (Nitrile) Rubber.

- FEP encapsulated Silicone Rubber Gaskets also available.

Surface Finish: (Non-Lined Fittings only)

- All surface finishes are to ASME BPE-SF-O (No finish required).

- If a specified finish on a particular surface is required, please state on the enquiry and order.

Temperature and Pressure Ratings

- When used with a Buna N Gasket all sizes up to 16 Bar (230 psi) and up to a maximum temperature of 65˚C (149˚F).

- When used with FEP, Fluoro Rubber or other encapsulated gaskets all sizes up to 10 Bar (145 psi) and up to a maximum temperature of 204˚C (400˚F).

90˚Elbow Cam & Groove Fittings (PTFE Lined Only)

- 90˚ Elbow Integral PTFE lined Cam & Groove Fittings are available for sizes 1”, 11/2” and 2” - Consult Aflex Hose for details.

Notes for Integral PTFE Lined Fittings Only:

- FEP Gaskets require higher clamping forces to flatten the Seal and make the joint. This is made easier by ‘pre-setting’ these gaskets by clamping Polypropylene Cam Male Inserts to the assembled fittings, which must then be kept in place during storage, until use.

- Any Customer’s Own ‘Special’ Gaskets must be pre-supplied to Aflex for special assembly and testing of hose assemblies, to ensure suitability.

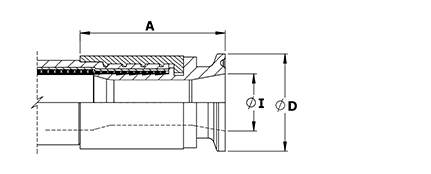

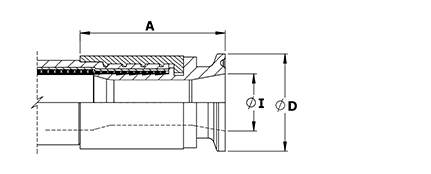

Swivelling, Locking Arm Female Cam and Groove Fittings

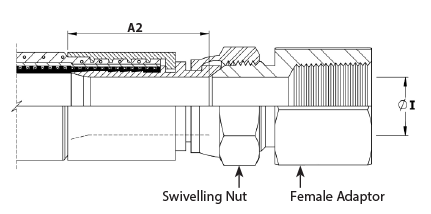

- Non-Lined

|

| Nominal Hose Size |

*Fitting Length A |

Cam Sleeve Inside Diameter D |

Fitting Inside Diameter I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 3/4 |

20 |

2.10 |

53.00 |

1.26 |

32.0 |

0.62 |

15.75 |

0.58 |

1.28 |

| 1 |

25 |

2.32 |

59.00 |

1.45 |

37.0 |

0.85 |

21.50 |

0.72 |

1.58 |

| 1 1/4 |

32 |

2.54 |

64.60 |

1.81 |

46.0 |

1.03 |

26.21 |

1.10 |

2.42 |

| 1 1/2 |

40 |

2.65 |

67.20 |

2.12 |

54.0 |

1.25 |

31.75 |

1.21 |

2.66 |

| 2 |

50 |

3.11 |

79.00 |

2.52 |

64.0 |

1.76 |

44.60 |

1.48 |

3.26 |

| 21/2 |

65 |

2.99 |

76.00 |

3.01 |

76.5 |

2.25 |

57.15 |

1.42 |

3.12 |

| 3 |

80 |

2.80 |

71.00 |

3.63 |

92.2 |

2.63 |

66.70 |

1.88 |

4.14 |

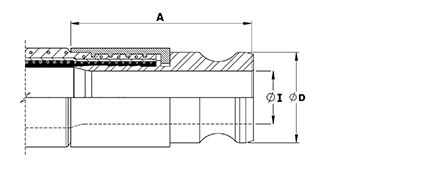

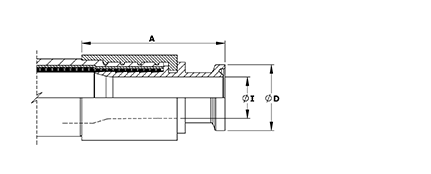

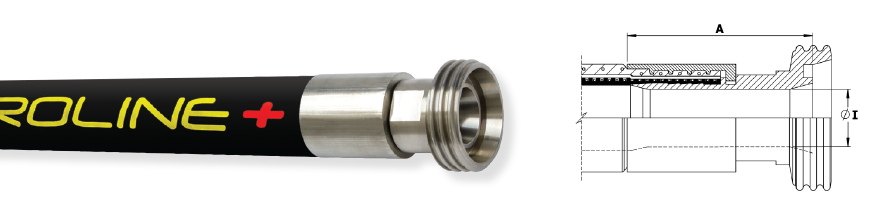

Fixed or Swivelling, Locking Arm Female Cam and Groove Fitting

- Integral PTFE Lined

|

| Nominal Hose Size |

*Fitting Length A |

Cam Sleeve Inside Diameter D |

Fitting Inside Diameter I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 3/4 |

20 |

2.16 |

54.75 |

1.26 |

32.0 |

0.76 |

18.6 |

0.42 |

0.93 |

| 1 |

25 |

2.72 |

69.00 |

1.46 |

37.0 |

1.01 |

25.2 |

0.59 |

1.30 |

| 1 1/4 |

32 |

2.56 |

65.50 |

1.81 |

46.0 |

1.26 |

32.0 |

0.98 |

2.16 |

| 1 1/2 |

40 |

2.61 |

66.35 |

2.13 |

54.0 |

1.53 |

38.6 |

1.15 |

2.50 |

| 2 |

50 |

2.97 |

75.35 |

2.52 |

64.0 |

2.03 |

51.2 |

1.40 |

3.08 |

| *21/2 |

65 |

5.31 |

135.0 |

3.01 |

76.5 |

2.36 |

60.0 |

1.17 |

2.57 |

| *3 |

80 |

5.45 |

138.4 |

3.63 |

92.2 |

2.87 |

73.0 |

1.40 |

3.07 |

*PTFE Lined 21/2" and 3" sizes are fixed only

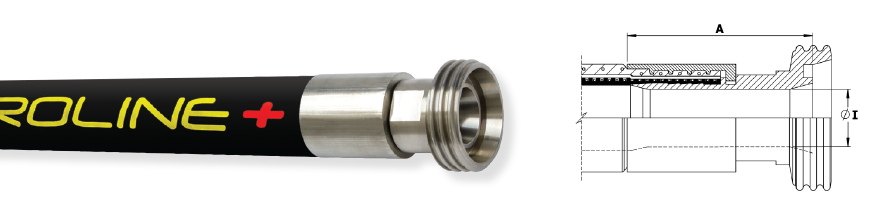

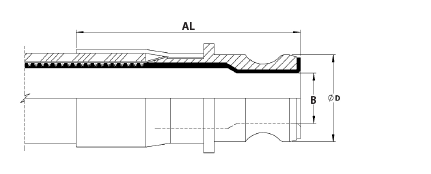

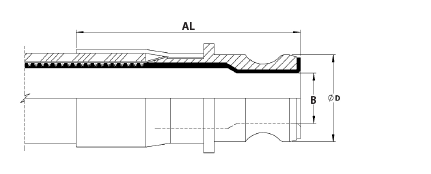

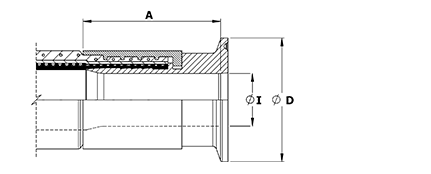

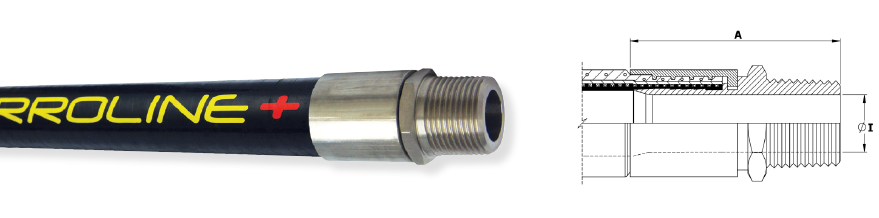

Corroline+ Male Cam & Groove Fittings & Lined Flange Adaptors

End Fitting Specifications

- Generally in accordance with A-A-59326 (replaces MIL-C-27487) and EN14420-1 (replaces DIN 2828), and all are fully interchangeable.

Temperature and Pressure Ratings

- Temperature and pressure determined by the type of gasket in the Female connecting component and the hose grade.

End Fitting Materials

- Fittings in Grade 316L SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

- Adaptor Flange Only in Grade 304 SS

Surface Finish: (Non-Lined Fittings only)

- All surface finishes are to ASME BPE-SF-O (No finish required).

- If a specified finish on a particular surface is required, please state on the enquiry and order.

|

| Non-Lined Cam & Groove Male Fitting |

|

| Integral PTFE Lined Cam & Groove Male Fitting |

|

| Nominal Hose Size |

Outside Diameter D |

Non-Lined Fitting Length A |

Non-Lined Inside Diameter I |

PTFE Lined Fitting Length AL |

PTFE Lined Inside Diameter B

|

Weight of Fitting Non-Lined

|

Weight of Fitting PTFE Lined |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

Kg |

Lbs |

| 3/4 |

20 |

1.26 |

32.0 |

2.40 |

61.0 |

0.62 |

15.75 |

2.82 |

71.58 |

0.71 |

18.6 |

0.22 |

0.49 |

0.35 |

0.77 |

| 1 |

25 |

1.46 |

37.0 |

3.00 |

77.0 |

0.85 |

21.50 |

3.74 |

95 |

0.81 |

20.7 |

0.33 |

0.72 |

0.45 |

0.99 |

| 11/4 |

32 |

1.79 |

45.5 |

3.54 |

90.0 |

1.03 |

26.21 |

3.62 |

92 |

0.97 |

24.8 |

0.57 |

1.25 |

0.45 |

1.09 |

| 11/2 |

40 |

2.11 |

53.5 |

3.70 |

94.0 |

1.25 |

31.75 |

3.98 |

101 |

1.35 |

33.5 |

0.78 |

1.71 |

0.84 |

1.85 |

| 2 |

50 |

2.48 |

63.0 |

4.45 |

113.0 |

1.76 |

44.60 |

4.61 |

117 |

1.72 |

41.5 |

1.08 |

2.37 |

1.10 |

2.42 |

| 21/2 |

65 |

2.98 |

75.8 |

4.13 |

105.0 |

2.23 |

56.6 |

6.50 |

165 |

2.17 |

55.0 |

1.22 |

2.68 |

1.17 |

2.57 |

| 3 |

80 |

3.60 |

91.5 |

4.76 |

120.8 |

2.87 |

73.0 |

6.98 |

177.4 |

2.84 |

72.2 |

1.79 |

3.94 |

1.45 |

3.20 |

PTFE Lined Male Cam & Groove X Flange Adaptors

|

| Note: Other Flange Specifications and Pressure Ratings are also available. Non-Lined adaptors and Female Cam & Groove X Flange Adaptors are also available, to special order. |

|

| Cam Action Adaptor Size |

Flange Size & Specification |

øD |

A |

øI |

Weight of Fitting |

| in |

mm |

|

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1 |

25 |

1” ANSI 150 |

2.00 |

50 |

41/8 |

105 |

0.84 |

21 |

1.246 |

2.75 |

| 1 |

25 |

DN25/PN16 |

2.58 |

64 |

41/8 |

105 |

0.84 |

21 |

1.538 |

3.39 |

| 1 1/2 |

40 |

11/2” ANSI 150 |

2.87 |

73 |

43/8 |

118 |

1.35 |

34 |

2.228 |

4.92 |

| 1 1/2 |

40 |

DN40/PN16 |

3.47 |

88 |

43/8 |

118 |

1.35 |

34 |

2.753 |

6.07 |

| 2 |

50 |

2” ANSI 150 |

3.63 |

92 |

43/8 |

118 |

1.69 |

43 |

3.359 |

7.40 |

| 2 |

50 |

DN50/PN16 |

4.00 |

102 |

43/8 |

118 |

1.69 |

43 |

3.714 |

8.19 |

Corroline+ Sanitary & Mini-Sanitary Triclamp (Triclover) Fittings

Introduction

There are many different specifications, dimensions and surface finishes for triclamp fittings. Those listed below are the popular fittings, which are stocked as standard fittings by Aflex.

All the alternative fittings can be supplied to special order if the following information can be given;

- Flange diameter D and Outlet diameter I

- Hose size if known, or Aflex can recommend a hose size to suit

- The internal Surface Finish, if it is required to be better than the ASME BPE SF3 surface finish of <0.76µm.Ra = <30µ in Ra non-electropolished.

- Standard (see below) if known

Standards

- ASME BPE

- DIN 32676 (types A, B and C are available)

- BS 4825 Pt.3 (equivalent to ASME BPE)

- ISO 1127

End Fitting Materials

- Fittings in AISI 316L = EN 1.4404 = BS 316 S11

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

- Fittings for DIN32676 are available in 1.4435 (316L)

- Fittings in 1.4571, Hastelloy, Monel, PVDF and other materials to special order

Temperature and Pressure Ratings

- Pressures up to 16 Bar (230 psi)

- Temperatures up to 120˚C (250˚F) with EPDM Gaskets

- Temperatures up to 180˚C (356˚F) with PTFE, Silicone or Viton Gaskets

- Higher Pressures and Temperatures with Special Clamps and Gaskets.

Internal Surface Finish Specifications

- ASME BPE SF3 (mechanical polish, not electropolished) Surface Finish, Maximum reading:

<0.76µm Ra = <30µ in. Ra

- ASME BPE SF4 (mechanical polish and electropolished) Surface Finish, Maximum reading:

<0.375µm Ra = <15µ in. Ra (SF4 is the highest level of surface finish specified in ASME BPE,

and the standard, stocked fittings listed are all to this finish).

- DIN 32676 H4 (mechanical polish, not electropolished) Surface Finish, Average reading:

<0.4µm Ra = <16µ in. RA. If the standard SF4 finish is not acceptable, H4 must be requested

on the enquiry/order.

Note: ASME BPE Triclamp suppliers often quote an ‘Average’ of surface finish reading only, for example ‘average 15 Ra or better’, but this is not in accordance with the stricter ASME BPE requirement that a ‘Maximum’ for individual readings should be complied with.

|

| Mini-Sanitary Triclamp Fittings |

Standard Fittings Available:

|

|

| Nominal Hose Size |

Flange Diameter D |

Outlet Diameter I |

Fitting Length A |

Specifications |

| in |

in |

mm |

in |

mm |

in |

mm |

ASME BPE |

DIN 32676 |

| 1/4 |

0.984 |

25.0 |

0.172 |

4.37 |

1.3 |

33 |

-SF4 |

- |

| 1/4 |

0.984 |

25.0 |

3/8 |

9.53 |

1.3 |

33 |

-SF4 |

Type C |

| 3/8 |

0.984 |

25.0 |

0.305 |

7.75 |

1.7 |

42 |

-SF4 |

- |

| 3/8 |

0.984 |

25.0 |

3/8 |

9.53 |

1.7 |

42 |

-SF4 |

Type C |

| 1/2 |

0.984 |

25.0 |

5/8 |

15.88 |

1.7 |

44 |

-SF4 |

Type C |

| 1/2 |

0.984 |

25.0 |

3/8 |

9.5 |

1.7 |

44 |

-SF4 |

Type C |

| 3/4 |

0.984 |

25.0 |

5/8 |

15.85 |

2.0 |

50 |

-SF4 |

Type C |

|

| Sanitary Triclamp Fittings |

Standard Fittings Available

|

|

| Nominal Hose Size |

Flange Diameter D |

Outlet Diameter I |

Fitting Length A |

Specifications |

| in |

in |

mm |

in |

mm |

in |

mm |

ASME BPE |

DIN 32676 |

| 3/4 |

1.340 |

34.0 |

5/8 |

15.88 |

2.0 |

50 |

-SF4 |

Type C |

| 3/4 |

1.340 |

34.0 |

0.630 |

16.0 |

2.0 |

50 |

- |

Type A |

| |

|

|

|

|

|

|

|

|

| 1/2 |

1.984 |

50.5 |

7/8 |

22.2 |

1.7 |

44 |

-SF4 |

Type C |

| 1/2 |

1.984 |

50.5 |

1 3/8 |

34.8 |

1.7 |

44 |

-SF4 |

Type C |

| 3/4 |

1.984 |

50.5 |

0.713 |

18.1 |

1.8 |

45 |

ISO1127 |

Type B |

| 3/4 |

1.984 |

50.5 |

7/8 |

22.1 |

1.8 |

45 |

-SF4 |

Type C |

| 3/4 |

1.984 |

50.5 |

5/8 |

15.88 |

1.8 |

45 |

-SF4 |

Type C |

| 1 |

1.984 |

50.5 |

7/8 |

22.2 |

2.3 |

58 |

-SF4 |

Type C |

| 1 |

1.984 |

50.5 |

1 3/8 |

34.8 |

2.3 |

58 |

-SF4 |

Type C |

| 1 1/2 |

1.984 |

50.5 |

1 3/8 |

34.8 |

2.6 |

67 |

-SF4 |

Type C |

| |

|

|

|

|

|

|

|

|

| 1 1/2 |

2.516 |

64.0 |

1 7/8 |

47.6 |

2.6 |

67 |

-SF4 |

Type C |

| 2 |

2.516 |

64.0 |

1 7/8 |

47.6 |

3.1 |

78 |

-SF4 |

Type C |

| 21/2 |

3.05 |

77.5 |

2.37 |

60.2 |

2.80 |

71 |

-SF4 |

Type C |

| 3 |

3.58 |

91 |

2.87 |

72.9 |

3.17 |

80.4 |

-SF4 |

Type C |

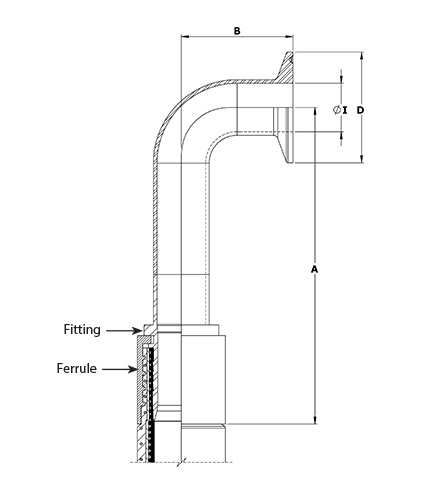

Corroline+ Sanitary Triclamp (Triclover) Fittings - 90° Elbow

End Fitting Specifications

- BS4825 Pt 3

- ASME-BPE-a

- Others to Special Order

End Fitting Materials

- Fittings in Grade AISI 316L = EN 1.4404 = BS 316 S11

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

Surface Finish:

- The internal surface is to ASME BPE-SF-3 (<0.76 µm Ra, not electropolished).

- If a specified finish on a particular surface is required, please state on the enquiry and order.

Outlet Diameters

The outlet diameters as listed are in accordance with BS4825. The ASME specification, however, requires these diameters to be 0.005” (0.125mm) less in each case. An Outlet Diameter tolerance of +0.000 -0.005” has therefore been applied, so that the same fitting satisfies requirements of both specifications.

Temperature and Pressure Ratings

- Pressures up to 16 Bar (230 psi)

- Temperatures up to 120˚C (250˚F) with EPDM Gaskets

- Temperatures up to 180˚C (356˚F) with PTFE, Silicone or Viton Gaskets

- Higher Pressures and Temperatures with Special Clamps and Gaskets.

Standard Fittings Available:

| Nominal Hose Size |

*Centre Line to Fitting End A |

Centre Line to Face B |

Flange Diameter D |

Outlet Diameter I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

5.12 |

130.0 |

1.60 |

41.0 |

0.98 |

25.0 |

3/8 |

9.5 |

0.09 |

0.21 |

| 3/4 |

20 |

5.26 |

133.5 |

1.60 |

41.0 |

0.98 |

25.0 |

5/8 |

16.0 |

0.14 |

0.30 |

| 1 |

25 |

5.64 |

143.2 |

2.00 |

51.0 |

1.98 |

50.5 |

7/8 |

22.2 |

0.26 |

0.58 |

| 11/2 |

40 |

6.69 |

170.0 |

2.75 |

70.0 |

1.98 |

50.5 |

13/8 |

34.9 |

0.45 |

1.00 |

| 2 |

50 |

8.10 |

205.7 |

3.50 |

88.9 |

2.16 |

64.0 |

17/8 |

47.6 |

0.75 |

1.65 |

| 21/2 |

65 |

7.32 |

186.0 |

4.25 |

108.0 |

3.05 |

77.5 |

2.37 |

60.2 |

1.48 |

3.25 |

| 3 |

80 |

10.43 |

265.0 |

5.00 |

127.0 |

3.58 |

91.0 |

2.87 |

72.9 |

1.99 |

4.38 |

DIN 11851 Male & Female Fittings

End Fitting Materials

- Spigots in Grade 316L SS (Non-Lined Spigot in 1.4571*)

- Nuts in Grade 304 SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

* 1.4571 is a special grade of 316 stainless steel, equivalent to AISI 316Ti

Surface Finish:

- All surface finishes are to ASME BPE-SF-3 > 0.76 µm Ra mechanical polish.

- If a specified finish on a particular surface is required, please state on the enquiry and order.

End Fitting Specifications

- Generally to DIN 11851 specifications.

Temperature & Pressure Ratings

- Sizes up to 11/2” MWP = 40 Bar (580 psi) up to 140˚C (284˚F)

- Sizes 2” to 3” MWP = 25 Bar (360 psi) up to 140˚C (284˚F)

Except where hose pressure ratings are lower - see Specifications and Properties

DIN11851 Female Fitting - Non Lined

| Nominal Hose Size |

I Diameter |

Fitting Length A |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

15 |

0.37 |

9.4 |

1.63 |

41.5 |

0.20 |

0.44 |

| 3/4 |

20 |

0.62 |

15.8 |

1.87 |

47.5 |

0.34 |

0.76 |

| 1 |

25 |

0.85 |

21.5 |

2.33 |

59.2 |

0.49 |

1.08 |

| 1 1/4 |

32 |

1.03 |

26.2 |

2.58 |

65.5 |

0.64 |

1.40 |

| 1 1/2 |

40 |

1.25 |

31.8 |

2.76 |

70.0 |

0.85 |

1.86 |

| 2 |

50 |

1.76 |

44.6 |

3.23 |

82.0 |

1.20 |

2.04 |

| 21/2 |

65 |

2.25 |

57.2 |

3.03 |

77.0 |

1.59 |

3.50 |

| 3 |

80 |

2.63 |

66.7 |

2.97 |

75.5 |

2.04 |

4.49 |

DIN11851 Male Fitting - Non Lined

| Nominal Hose Size |

I Diameter |

Fitting Length A |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

15 |

0.37 |

9.4 |

1.82 |

46 |

0.14 |

0.30 |

| 3/4 |

20 |

0.62 |

15.8 |

2.05 |

52 |

0.28 |

0.62 |

| 1 |

25 |

0.85 |

21.5 |

2.68 |

68 |

0.40 |

0.87 |

| 1 1/4 |

32 |

1.03 |

26.2 |

2.48 |

63 |

0.55 |

1.21 |

| 1 1/2 |

40 |

1.25 |

31.8 |

2.84 |

72 |

0.76 |

1.68 |

| 2 |

50 |

1.76 |

44.6 |

3.23 |

82 |

0.92 |

2.04 |

| 21/2 |

65 |

2.25 |

57.15 |

3.23 |

82 |

1.27 |

2.79 |

| 3 |

80 |

2.63 |

66.7 |

3.23 |

82 |

1.62 |

3.56 |

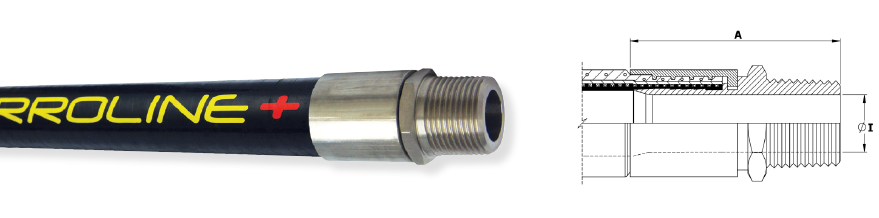

NPT & BSPT Fittings

End Fitting Specifications

- NPT Taper Threads to American National Standard Pipe Taper Thread design to ANSI/AMSE B1.20.1.

- BSPT Threads to British Standard Pipe Taper Thread design to BS21

Alternatives - Parallel Threads, Metric Threads and Others.

End Fitting Materials

- Fittings in Grade 316L SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

- Available in other materials to special order

Alternatives - Hydraulic design BSPT Male Fittings in Zinc Plated Carbon Steel, to special order.

Surface Finish:

- All surface finishes are to ASME BPE-SF-O (No finish required).

- If a specified finish on a particular surface is required, please state on the enquiry and order.

Fixed Male NPT or BSPT

| Nominal Hose Size | NPT or BSPT Thread Size |

*Fitting Length A |

Fitting Inside Diameter I |

Weight of Fitting |

| in |

mm |

in |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

1/2 |

2.40 |

61 |

0.37 |

9.40 |

0.14 |

0.30 |

| 3/4 |

20 |

3/4 |

2.68 |

68 |

0.62 |

15.75 |

0.25 |

0.54 |

| 1 |

25 |

1 |

3.07 |

78 |

0.85 |

21.50 |

0.33 |

0.73 |

| 1 1/4 |

32 |

1 1/4 |

3.58 |

91 |

1.03 |

26.21 |

0.61 |

1.34 |

| 1 1/2 |

40 |

1 1/2 |

3.82 |

97 |

1.25 |

31.75 |

0.81 |

1.78 |

| 2 | 50 |

2 |

4.57 |

116 |

1.76 |

44.60 |

1.17 |

2.58 |

| 21/2 | 65 |

21/2 |

5.31 |

135 |

2.25 |

57.15 |

1.84 |

4.04 |

| 3 | 80 |

3 |

5.39 |

137 |

2.63 |

66.7 |

2.49 |

5.47 |

Fixed Female NPT

| Nominal Hose Size |

NPT Thread Size |

*Fitting Length A |

Fitting Inside Diameter I |

Weight of Fitting |

| in |

mm |

in |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

1/2 |

2.40 |

61 |

0.37 |

9.40 |

0.18 |

0.39 |

| 3/4 |

20 |

3/4 |

2.52 |

64 |

0.62 |

15.75 |

0.24 |

0.54 |

| 1 |

25 |

1 |

3.23 |

82 |

0.85 |

21.50 |

0.37 |

0.81 |

| 1 1/2 |

40 |

1 1/2 |

3.62 |

92 |

1.25 |

31.75 |

0.83 |

1.82 |

| 2 | 50 |

2 |

4.13 |

105 |

1.76 |

44.60 |

1.24 |

2.72 |

BSP 60° Cone Seat Female Fittings

End Fitting Specifications

- BSPP Threads to British Standard Pipe Parallel Thread design to BS21, 60˚ Cone Seat design, or Flat Seat.

End Fitting Materials

- Spigots in Grade 316L SS

- Nuts in Grade 316L SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

Alternatives:

- Hydraulic design Cone Seat Female Unions can be supplied in Zinc Plated Carbon Steel to special order.

- Lug Nuts can be supplied in Gun Metal (Bronze) if required.

Surface Finish :

- All surface finishes are to ASME BPE-SF-O (No finish required).

- If a specified finish on a particular surface is required, please state on the enquiry and order.

| Nominal Hose Size | NPT or BSPT

Thread Size | *Fitting Length A | Fitting Inside Diameter I | Weight of Fitting |

|---|

| in | mm | in | in | mm | in | mm | kg | lbs |

|---|

| 1/2 | 13 | 1/2 | 1.46 | 37 | 0.37 | 9.40 | 0.09 | 0.21 | | 3/4 | 20 | 3/4 | 1.89 | 48 | 0.62 | 15.75 | 0.20 | 0.44 | | 1 | 25 | 1 | 2.17 | 55 | 0.85 | 21.50 | 0.33 | 0.72 | | 11/4 | 32 | 11/4 | 2.48 | 63 | 1.03 | 26.21 | 0.49 | 1.07 | | 11/2 | 40 | 11/2 | 2.87 | 73 | 1.25 | 31.75 | 0.79 | 1.73 | | 2 | 50 | 2 | 2.91 | 74 | 1.76 | 44.60 | 1.07 | 2.36 | | 21/2 | 65 | 21/2 | 3.15 | 80 | 2.25 | 57.15 | 1.37 | 3.02 | | 3 | 80 | 3 | 3.21 | 81.5 | 2.63 | 66.7 | 2.10 | 4.62 |

37° JIC Female Fittings

End Fitting Specifications

- SAE J514 37˚ Flare JIC Female Fitting

- 37˚ JIC Male-to-NPT Male/Female Adaptors

- NPT Threads to ANSI/AMSE B1.20.1

Temperature and Pressure Ratings

- Same Maximum Working Pressure and Temperature as for the relevant size of Corroline+ Hose,

in Specification & Properties.

Note: Not usable with SAE 45˚ Flare fittings which have the same thread.

End Fitting Materials

- Spigots in Grade 316L SS

- Nuts in 316L SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

Alternatives:

- Available in other materials to special order

Surface Finish:

- All surface finishes are to ASME BPE-SF-O (No finish required).

- If a specified finish on a particular surface is required, please state on the enquiry and order.

| Nominal Hose Size |

37° JIC Thread Size |

*Fitting Length A |

Hex Size H |

Fitting Inner Diameter I |

Weight of Fitting |

| in |

mm |

in |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

3/4 - 16 |

1.57 |

40 |

0.88 |

22.2 |

0.37 |

9.40 |

0.09 |

0.20 |

| 3/4 |

20 |

11/16 - 12 |

1.89 |

48 |

1.25 |

31.7 |

0.62 |

15.75 |

0.20 |

0.44 |

| 1 |

25 |

15/16 - 12 |

2.28 |

58 |

1.50 |

38.1 |

0.85 |

21.50 |

0.30 |

0.66 |

| 11/2 |

40 |

17/8 - 12 |

2.72 |

69 |

2.25 |

57.1 |

1.25 |

31.75 |

0.62 |

1.37 |

| 2 |

50 |

21/2 - 12 |

3.27 |

83 |

2.88 |

73.0 |

1.76 |

44.60 |

1.10 |

2.42 |

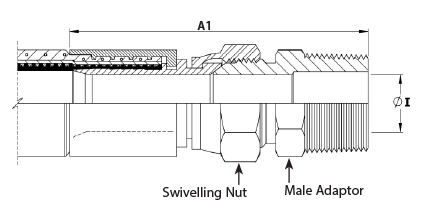

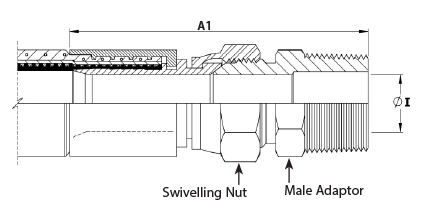

JIC to NPT Male Union (including a JIC Male to NPT Male Adaptor)

|

| Nominal Hose Size |

*Male Union Length A1 |

Weight of Fitting |

| in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

2.95 |

75 |

0.17 |

0.37 |

| 3/4 |

20 |

3.74 |

95 |

0.34 |

0.75 |

| 1 |

25 |

4.49 |

114 |

0.64 |

1.40 |

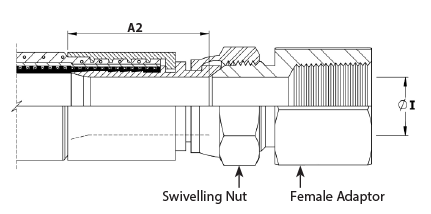

JIC to NPT Female Union (including a JIC Male to NPT Female Adaptor)

|

| *Female Union Length A2 |

Fitting Inner Diameter |

Weight of Fitting |

| in |

mm |

in |

mm |

Kg |

Lbs |

| 3.07 |

78 |

2.95 |

75 |

0.17 |

0.37 |

| 3.78 |

96 |

3.74 |

95 |

0.34 |

0.75 |

| 4.17 |

106 |

4.49 |

114 |

0.64 |

1.42 |

|

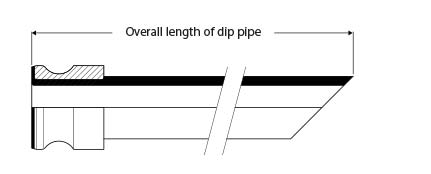

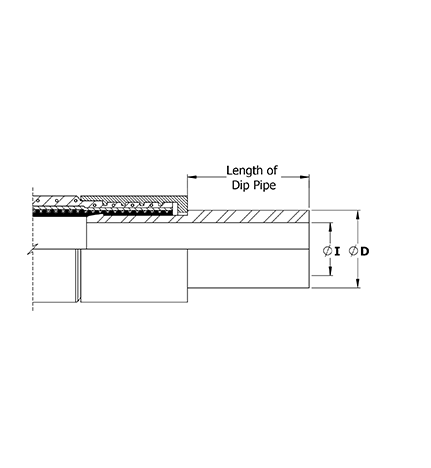

| Fixed Dip Pipe (90° Elbow) |

|

| Detachable Dip Pipes |

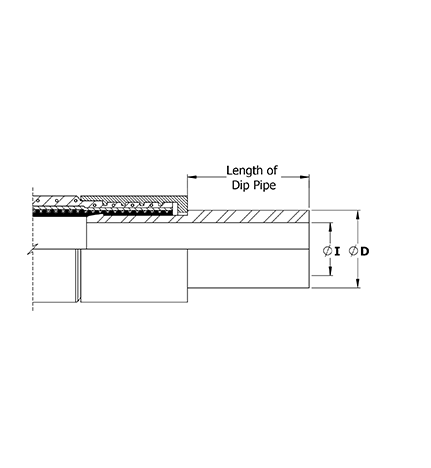

PTFE Dip Pipe Fittings

Fixed Dip Pipes

Description

Fixed Dip Pipes are fairly rigid, thick wall PTFE tubes, either straight or 90˚ elbowed, which are directly crimped to the end of Corroline+ hoses. They are designed for insertion into drums, tanks and reaction vessels in order to suction drain (or inject) process fluids transferred through the hose.

Materials

- Standard dip pipes are in anti-static (AS) PTFE

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

How to order

Specify the size and material of the dip pipe, whether it is straight or 90˚ elbowed. Give the length of the straight leg of the dip pipe and the length of the rest of the hose assembly separately.

Maximum Working Pressures

Dip Pipes are normally only tested to 6 Bar Pressure, and are not suitable for use at pressures higher than 3 Bar. They are usable at negative pressure up to -0.9bar vacuum..

If higher pressure ratings are required, consult Aflex Hose.

Lengths

Dip Pipes are supplied as standard in 1 metre straight lengths, but can be supplied in any length to individual requirements.

Note: Not available as a Hydraulic Fitting.

| Nominal Hose Bore Size |

Approximate Dip Pipe Dimentions |

| Outside Diameter D |

Inside Diameter I |

| in |

mm |

in |

mm |

in |

mm |

| 3/4 |

20 |

0.87 |

22 |

0.51 |

13 |

| 1 |

25 |

1.14 |

29 |

0.83 |

21 |

| 11/2 |

40 |

1.54 |

39 |

1.00 |

27 |

| 2 |

50 |

2.17 |

55 |

1.58 |

40 |

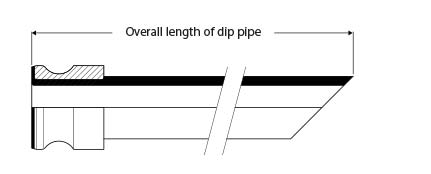

Detachable Dip Pipes

Description

As Fixed Dip Pipes above, but connected to the hose through an end fitting, not by crimping direct to the hose.

Design

A straight, or 90˚ elbowed anti-static PTFE Dip Pipe, fitted with a Flange or Cam & Groove Male PTFE Lined & Flared end fitting.

The most usual end fitting is a Cam Male (as shown), so the dip pipe can then be connected to a hose with a Cam Female end fitting.

Specifications

As above for Fixed Dip Pipes

Detachable Dip Pipe

|