Corroflon Temperatures, Pressures & Flow Rates |

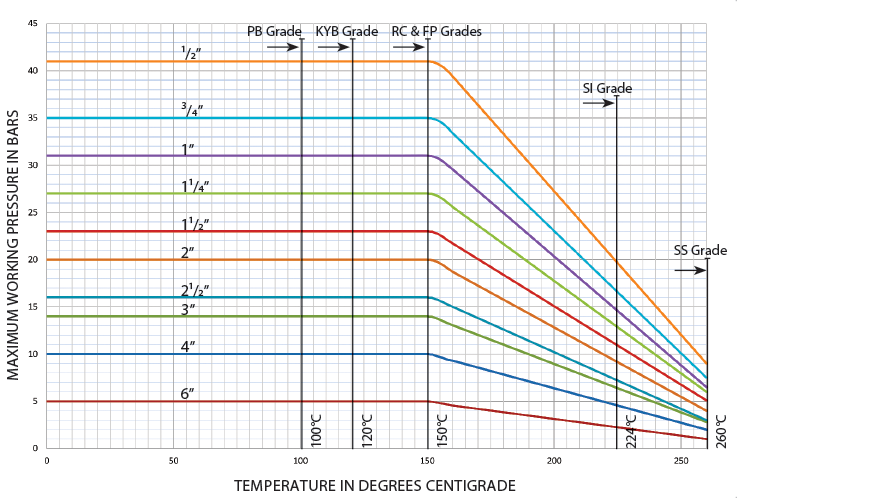

Temperature vs PressureMaximum Working Pressure (MWP) Variation with Temperature:Hose with SS Braid as per Graph. Hose with PB Braid, pressure as listed from -30˚C to +80˚C and 50% less from 80˚C to 100˚C. Hose with RC, FP and SI grades as per Graph, BUT only within the temperature range for the particular grade of rubber cover, as given below. Maximum Operating Temperatures (Internal Fluid Only) for different hose grades:SS -73˚C to +260˚C (Subtract 20˚C from the above maximum temperature limits if the temperature is external to the hose). Temperature vs VacuumAll sizes of Corroflon GP,SS and AS, SS are usable at vacuum to -0.9bar up to 150˚C up to 2”. Above this, the vacuum resistance should be reduced 1% for every degree above 150˚C. Other grades the same, BUT ONLY within the temperature limits for the particular hose grade.

Temperature & MWP Graph for Corroflon GP, SS and AS, SS Flow RatesFor maximum flow rates, it is better to use the smoothbore Bioflex hose if possible, because the convoluted bore of Corroflon creates turbulent flow, which reduces flow rates. Corroflon Hose - Flow Rate CalculationIf it is required to determine the flow rate of a particular hose assembly, or if it is required to determine the pressure required to generate a certain flow rate, then this can sometimes be approximately calculated by the Corroflon supplier. It should be noted that calculations can only be made for fluids with a viscosity equal to water, and for hose assemblies with PTFE lined end fittings (no bore restrictions at the ends of the hose). The following information should be given to the supplier: To calculate the Flow Rate in Cubic Metres per Hour:

OR To Calculate the Pressure Drop in bars over the length of the Hose Assembly:

WhistlingA ‘whistling’ noise may be created by turbulent flow when steam or other gasses are passed through a Corroflon hose at high flow rates. In such applications, Bioflex hose represents an alternative option which eliminates this problem. |

Our Commitment to Quality

Above all else, Carolina Components Group is committed to producing components of the highest quality.

Our customers can be assured that the products that they receive meet their stringent quality standards.

Carolina Components Group is a Member or Affiliate of: