|

Sizes, Grades, Bend Radii & Dimensions

| Nominal Hose Bore Size |

Bore Inside Convolutions |

Corroflon Grade (Braid & Cover) |

PTFE Liner Tube Wall Thickness |

O/D of Tube, Braid or Rubber |

Minimum Bend Radius |

* Maximum Continuous Hose Length |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

Feet |

Metres |

| 1/2 |

15 |

0.440 |

11.2 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

0.05 |

1.4 |

0.63

0.70

0.80

0.90

0.90

0.76 |

16.1

17.8

20.4

22.8

22.8

19.3 |

11/2

11/2

11/2

21/4

21/4

11/2 |

38

38

38

57

57

38 |

100

100

100

100

100

100 |

30

30

30

30

30

30 |

| 3/4 |

20 |

0.620 |

15.7 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

0.05 |

1.4 |

0.85

0.91

1.02

1.11

1.11

0.97 |

21.5

23.2

25.8

28.2

28.2

24.7 |

2

2

2

3

3

2 |

51

51

51

76

76

51 |

100

100

100

100

100

100 |

30

30

30

30

30

30 |

| 1 |

25 |

0.847 |

21.5 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

0.06 |

1.5 |

1.08

1.14

1.25

1.34

1.34

1.20 |

27.4

29.1

31.7

34.1

34.1

30.6 |

23/4

23/4

23/4

41/4

41/4

23/4 |

70

70

70

105

105

70 |

100

100

100

100

100

100 |

30

30

30

30

30

30 |

| 11/4 |

32 |

1.080 |

27.5 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

0.06 |

1.5 |

1.45

1.53

1.72

1.72

1.72

1.57 |

36.8

38.8

43.6

43.8

43.8

40.0 |

31/4

31/4

31/4

43/4

43/4

31/4 |

82

82

82

123

123

82 |

100

100

100

100

100

100 |

30

30

30

30

30

30 |

| 11/2 |

40 |

1.250 |

32.0 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

0.06 |

1.5 |

1.65

1.74

1.92

1.93

1.93

1.78 |

42.0

44.1

48.8

49.1

49.1

45.2 |

4

4

4

6

6

4 |

100

100

100

150

150

100 |

100

100

100

100

100

100 |

30

30

30

30

30

30 |

| 2 |

50 |

1.690 |

43.0 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

0.07 |

1.8 |

2.11

2.19

2.37

2.38

2.38

2.23 |

53.5

55.6

60.3

60.6

60.6

56.7 |

51/2

51/2

51/2

81/4

81/4

51/2 |

140

140

140

210

210

140 |

100

100

100

100

100

100 |

30

30

30

30

30

30 |

| 21/2 |

65 |

2.120 |

54.0 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

0.07 |

1.8 |

2.75

2.83

3.01

3.03

3.03

2.87 |

69.8

71.9

76.6

76.9

76.9

73.0 |

7

7

7

101/2

101/2

7 |

178

178

178

267

267

178 |

65

65

65

65

65

65 |

20

20

20

20

20

20 |

| 3 |

80 |

2.500 |

64.0 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

0.07 |

1.8 |

3.27

3.37

3.53

3.57

3.57

3.39 |

83.0

85.7

89.8

90.7

90.7

86.2 |

9

9

9

131/2

131/2

9 |

230

230

230

345

345

230 |

65

65

65

65

65

65 |

20

20

20

20

20

20 |

| 4 |

100 |

3.860 |

98.0 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

0.10 |

2.5 |

4.17

4.28

4.44

4.48

4.48

- |

106.0

108.7

112.8

113.7

113.7

- |

113/4

113/4

113/4

173/4

173/4

- |

300

300

300

450

450

- |

32

32

32

32

32

- |

10

10

10

10

10

- |

| 6 |

150 |

5.250 |

130.0 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

0.12 |

3.0 |

5.75

5.87

-

6.06

6.06

- |

146.0

149.0

-

154.0

154.0

- |

233/4

233/4

-

351/2

351/2

- |

600

600

-

900

900

- |

28

28

-

28

28

- |

8

8

-

8

8

- |

*Longer lengths may be available to special order if needed

Sizes, Grades, Pressure Ratings, Weights

Corroflon Sizes, Grades, Pressure Ratings & Weights

| Nominal Hose Bore Size |

Bore Inside Convolutions |

Corroflon Grade (Braid & Cover) |

Maximum Working Pressure of Hose |

Burst Pressure |

Weight per Unit Length |

| in |

mm |

in |

mm |

Bar |

psi |

Bar |

psi |

Kg/Mtr |

lb/ft |

| 1/2 |

15 |

0.440 |

11.2 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

6

41

31

41

41

15 |

87

595

450

595

595

215 |

24

450

150

450

450

61.5 |

350

6525

2175

6525

6525

890 |

0.21

0.33

0.26

0.49

0.49

0.23 |

0.14

0.22

0.17

0.33

0.33

0.15 |

| 3/4 |

20 |

0.620 |

15.7 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

5

35

26

35

35

13 |

70

505

375

505

505

190 |

20

240

105

240

240

52.5 |

290

3480

1520

3480

3480

760 |

0.29

0.45

0.36

0.56

0.56

0.31 |

0.19

0.30

0.24

0.38

0.38

0.21 |

| 1 |

25 |

0.847 |

21.5 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

4.5

31

23

31

31

11 |

65

450

334

450

450

160 |

18

200

93

200

200

46.5 |

260

2900

1350

2900

2900

675 |

0.45

0.70

0.56

0.98

0.98

0.49 |

0.30

0.47

0.38

0.66

0.66

0.33 |

| 11/4 |

32 |

1.080 |

27.5 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

4

27

20

27

27

10 |

58

390

290

390

390

145 |

16

180

81

180

180

40.5 |

230

2610

1175

2610

2610

585 |

0.53

0.82

0.66

1.12

1.12

0.57 |

0.36

0.55

0.44

0.75

0.75

0.38 |

| 11/2 |

40 |

1.250 |

32.0 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

3.5

23

17

23

23

9 |

50

335

245

335

335

130 |

14

120

69

120

120

34.5 |

205

1740

1000

1740

1740

500 |

0.97

1.50

1.20

1.90

1.90

1.05 |

0.65

1.01

0.80

1.27

1.27

0.70 |

| 2 |

50 |

1.690 |

43.0 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

3

20

15

20

20

8 |

44

290

215

290

290

115 |

12

100

60

100

100

30 |

175

1450

870

1450

1450

435 |

1.36

2.10

1.68

2.72

2.72

1.47 |

0.91

1.41

1.13

1.82

1.82

0.99 |

| 21/2 |

65 |

2.120 |

54.0 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

2.5

16

12

16

16

6 |

36

230

175

230

230

87 |

10

70

48

70

70

24 |

145

1015

695

1015

1015

350 |

1.68

2.58

2.06

3.10

3.10

1.81 |

1.13

1.73

1.38

2.08

2.08

1.21 |

| 3 |

80 |

2.500 |

64.0 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

2

14

10

14

14

5 |

29

205

145

205

205

73 |

8

60

42

60

60

21 |

115

870

610

870

870

305 |

2.14

3.29

2.63

3.95

3.95

2.30 |

1.43

2.20

1.76

2.65

2.65

1.54 |

| 4 |

100 |

3.860 |

98.0 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

1.5

10

8

10

10

- |

22

145

115

145

145

- |

6

40

30

40

40

-

|

87

580

435

580

580

-

|

3.18

5.05

3.98

6.12

6.14

- |

2.13

3.38

2.67

4.10

4.11

-

|

| 6 |

150 |

5.250 |

130.0 |

TO

SS

PB

SS,RC/FP

RC,SI

KYB |

0.75

5

-

5

5

- |

11

73

-

73

73

-

|

3

20

-

20

20

-

|

44

290

-

290

290

- |

6.50

10.00

-

12.00

12.00

-

|

4.36

6.70

-

8.04

8.04

-

|

EN16643 Hose Assembly Electrical Property Grades

The hose assembly electrical property grades and electrical resistance limits are defined within EN 16643 and tested in accordance with BS EN ISO 8031. Aflex Hose electrically conductive (EC) assemblies are defined in EN 16643 as electrically bonded and given the symbol M. M-grade assemblies exhibit a maximum electrical resistance of 100Ω between end fittings. Aflex Hose anti-static (AS) PTFE liners and rubber covers are termed static dissipative within EN 16643 and given the symbol Ω followed by letters that specify either the liner, cover or both; L=liner, C=cover, CL= cover & liner. Ω-grade covers or liners exhibit an electrical resistance of 103-108Ω.

The table below identifies each EN 16643 electrical grade for a hose assembly along with a brief description and example assembly configuration.

EN16643 Electrical Grade

For Hose Assembly |

EN16643 Description |

Example Hose

Assembly |

| Grade M |

Electrically bonded without static-dissipative lining or cover |

CFLN/GP SS SI

Ends ASA150 Lined

CFLN/GP TO

Ends JIC female |

| M/Ω-L |

Electrically bonded and static-dissipative lining |

CFLN/AS SS SI

Ends ASA150 Lined

CFLN/AS TO

Ends JIC female |

| M/Ω-C |

Electrically bonded and static-dissipative cover |

CFLN/GP SS RC

Ends ASA150 Lined |

| M/Ω-CL |

Electrically bonded and static-dissipative cover and lining |

CFLN/AS SS RC

Ends ASA150 Lined |

| I |

Electrically insulated

(no electrical bonding AND no static-dissipative layers) |

CFLN/GP PB

No helix

Ends ASA150 Lined |

| Ω-L |

Static dissipative lining without electrical bonding |

CFLN/AS TO

Ends ASA150 Lined

CFLN/AS SS

Ends ASA150 PP spigot and flange |

| Ω-C |

Static dissipative cover without electrical bonding |

CFLN/GP SS RC

Ends ASA150 PP spigot and flange |

| Ω-CL |

Static dissipative cover and lining without electrical bonding |

CFLN/AS SS RC

Ends ASA150 PP spigot and flange |

Hose Liners

GP - General Purpose Liner

Purpose

Corroflon GP, SS is the general purpose grade of hose and has been carefully designed to satisfy the widest range of application requirements.

Design & Approvals

The hose liner is manufactured from hose quality grade PTFE conforming to FDA requirements 21 CFR 177.1550 extruded into tube and helically convoluted. It also includes a heavy gauge Grade 304 stainless steel reinforcing wire helically wound into the external root of the convolutions to strengthen the convoluted shape. The braid is high tensile grade 304 stainless steel wire braid to give maximum protection to the hose against internal pressure and external abrasion.

Corroflon GP hose liner tube also conforms to USP Class VI at normal temperatures and at 121˚C (250˚F), see Quality Assurance & Certifications.

AS - Antistatic PTFE Liner

Purpose

Corroflon AS grade is an essential requirement in applications where there is the risk of an electrostatic charge build-up on the inside surface of the PTFE tube which may then discharge through the tube wall. Media passing through which create such a risk are fluids which have a Conductance of less than 10-8 S/m (Siemens per Metre), or 104 pS/m such as fuels, solvents, freons, some WFI (ultra-pure “Water for Injection”) and non-polar organics which are being transferred at a medium to high flow velocity.

All twin or multi phase media, and any non-mixing media, such as powder in air, or water droplets in steam, in gases or in oil, also colloidal fluids constitute a particular hazard for static charge generation, and always require grade AS.

A typical example involves cleaning systems which create a twin phase mixture passing through the hose at high velocity, such as WFI water purged out with air or nitrogen.

If in doubt, consult Aflex Hose.

Design & Approvals

Corroflon AS grade has an anti-static PTFE liner manufactured from FDA 21 CFR 177.1550 approved PTFE, and less than 2.5% of “high purity” Carbon Black material to FDA requirement 21 CFR 178.3297 and European Commission Directive 2007/19/EC. The carbon is encapsulated by the PTFE, and in normal, non-abrasive applications will not come loose to contaminate any fluid passing through. (This has been confirmed by Extractables and Leachables Tests in accordance with BPSA recommendations).

Corroflon AS hose liner tube also conforms to USP Class VI at normal temperatures and at 121˚C (250˚F), see Quality Assurance & Certifications.

Antistatic Hose Assemblies

When “AS” (Antistatic) grade hose is specified, then the hose or hose assembly supplied will be tested in accordance with EN ISO 8031 and meet the Antistatic requirements of EN 16643. This requires, for an antistatic liner or antistatic cover, that the resistance between an appropriately placed foam electrode and a metallic end fitting will be between 103 to 108 ohms per assembly. For hose assemblies which meet these requirements an appropriate Grade “Ω” marking is applied in accordance with EN 16643..

Note: When in service, at least one end fitting must be connected to earth, to permit dissipation of the static charge from the end fitting.

SP - Special Purpose Liner

Purpose

For applications requiring a higher temperature/pressure rating, greater flexibility and improved kink and crush resistance. Also for applications requiring vacuum resistance to -0.9bar for hose sizes larger than 2”.

Design

The convolutions are closer together, yielding greater radial strength to the hose design.

Specifications

As for Corroflon GP, except that the maximum working pressure for wire braided grades is increased by 25%, the weight per metre is increased by 30%, the actual through bore is reduced by 1/8” (3mm), the maximum continuous length is reduced by 50%, the minimum bend radius is reduced by 25% and the angle of cleanability is <80˚.

Available as SP (Natural) and SP, AS (Antistatic) Grades.

Hose Braids

SS - Stainless Steel Braid

Purpose

Stainless Steel braided hose is the general purpose product, and can be used in applications involving high temperatures and working pressures. High tensile AISI 304 stainless steel wire is used, to give maximum pressure resistance and external protection to the hose.

PB - Polypropylene Braid

Purpose

Polypropylene braided hose is often preferred to SS in applications involving frequent handling and movement of the hose, and where temperatures are within the range -30˚C to +100˚C (-22˚F to +212˚F). PB braid is lighter in weight, and any broken strands will not cut the operator’s hands. In addition, PB braid is not prone to “chloride stress corrosion”, and has generally good chemical resistance.

Note: Prolonged exposure to sunlight eventually results in UV degradation of PB braid.

KYB - Kynar Braid (Polyvinylidene Fluoride Monofilament)

Purpose

Kynar Braid is used in the same application as Hastelloy Braid, but only in applications where the reduced pressure ratings of KYB as listed are acceptable. A Safegard Sleeve is always recommended. Monel or Hastelloy wire should be used.

Full details about the applications should be given to Aflex Hose for evaluation and recommendations.

TO - Tube Only (no braid)

Purpose

TO grade hose (available in both GP and AS) is a lightweight hose, used in applications where working pressures are low and where there is no need for the physical protection offered by an external braid.

HB - Hastelloy Braid (C276 grade)

Purpose

Hastelloy Wire Braid is used instead of SS where severe chemical corrosion conditions exist around the outside of the hose. The most usual way in which this can happen is when Chlorine, Bromine, Hydrogen Fluoride, Hydrogen Chloride or Phosgene are being transferred. Diffusion of trace quantities of such fluids or gases through the PTFE liner can lead to atmospherically wetted halogen chemicals attacking the braid material, in which case the Hastelloy Braid would be resistant up to 60˚C (140˚F) maximum. This should only be used, however, in conjunction with a Monel or Hastelloy Helix Wire.

Full details about the applications should be given to Aflex Hose for evaluation and recommendations.

Specifications

Same as for SS in Specifications & Properties, except the Burst Pressures and the Maximum Working Pressures are both reduced to 80% of the SS pressures listed.

Also, the sizes range is restricted, from 1/2”up to 2” bore only.

SPECIAL NOTE:

EC - Electrical Continuity (Also known as “Electrically Bonded”)

The requirements for this are specified in the German Document BRG 132 and EN 16643, when tested in accordance with EN ISO 8031, which requires that the resistance between end fittings shall be <102 ohms per assembly. For hose assemblies which meet this requirement a Grade “M” marking can be applied in accordance with EN 16643.

Hose Rubber Covers

RC - EPDM Rubber Covered - Antistatic and Fire Proof Black Rubber Cover

Purpose

For the most rugged applications where the hose may be subjected to rough treatment and severe external abrasion. Also for hygienic applications, where the external cleanability of the hose is of prime importance and in applications where the hose is required to be Fire Proof, or to have an Antistatic cover.

Design

An SS braided hose has a black, antistatic EPDM external rubber cover extruded directly onto the braid to produce a super-smooth external surface finish. Sizes above 2” bore are hand-wrapped, not extruded.

EPDM has excellent chemical resistance, and the hose has a temperature range from -40˚C, -40˚F up to +150˚C, +302˚F.

Fire Proof

As well as providing an Antistatic cover, Corroflon RC hose is also Fire Proof in accordance with Specification BS5173 Section 103.13 part 6.2 (Fireproof). This specification calls for an 1100˚C (2012˚F) flame to be applied to the hose at minimum bend radius, maximum operating pressure (water), and one end fitting under vibration. The hose must withstand at least 15 minutes without leakage.

Hose assemblies are Fire Resistant, but can be rendered Fire Proof by the addition of DRC-300 at both ends - see below.

Corroflon RC hose meets the requirements of German Safety Regulation TRBF 131/2 and EN 16643 flame resistance.

Antistatic

Corroflon RC hose is antistatic (AS) in accordance with EN 16643 limits and tested in accordance with EN ISO 8031.

SI - Silicone Rubber Cover

Purpose

As for RC hose, but where the hose may be required to withstand temperatures from -73˚C, -100˚F up to +224˚C, +435˚F. SI grade hose is semi-transparent, allowing visual monitoring of the braid.

Design

An SS braided hose assembly has an external smooth finish, platinum cured silicone rubber cover extruded (>50 metres) or hand-wrapped (<50 metres), and vulcanised directly onto the braid.

Specifications

The Silicone rubber cover has been tested and conforms to the requirements of USP Class VI, see Quality Assurance & Certifications.

RC-300 - Rubber Covered 300mm at End

Purpose

In applications where excessive flexing of the hose at the end fitting occurs, it is sometimes necessary to ‘stiffen’ the hose in this area, to prevent kinking.

Design

A layer of rubber is hand-wrapped and vulcanised directly to the ferrule, and 300mm (12 inch) along the hose from the fitting. This can be done either on an SS braided hose (RC-300 or SI-300) or on a rubber covered hose as a 300mm (12 inch) long double layer of rubber at the end (DRC-300 or DSI-300).

Hose External Protections

SG - Safegard Protection Sleeve

Purpose

To protect the hose against external abrasion and mechanical damage. For use in applications where maximum external protection is required with minimum extra hose weight. Particularly useful with PB or KYB hose, where a rubber cover is not an option.

Design

A lightweight black, HDPE (High Density Poly Ethylene) strip spirally wound around the outside of the hose over its whole length, secured to each end fitting by crimping under a SS ferrule.

Limitations

Safegard is applicable to all hose types and all hose sizes from 1/2” up to 4”.

Safegard is limited to use within a temperature range from -40˚C (-40˚F) up to +110°C (230°F). Internal fluid temperatures up to 140°C (284°F) are acceptable, when external temperatures are ambient.

The minimum hose assembly length must be doubled, if Safegard is being used and the maximum assembly lengths for all sizes are capped at 20 metres (65 feet).

The other hose usage limitation specifications are not altered by the addition of Safegard.

Safegard is available with anti-static properties and complies with the requirements of a static-dissipative cover within EN 16643. Request details upon enquiry.

SR - Scuff Rings

Purpose

For medium duty applications where the hose requires some protection against abrasion when dragged over the ground, but where a full rubber cover would be too heavy and cumbersome. Also for PB and KYB braided hose, which cannot be Rubber Covered.

Design

Specially moulded abrasion resistant rubber scuff rings are placed every half metre along the hose.

Limitations

Available for hose sizes 1” (25mm) to 2” (50mm) only. The operating temperature should not exceed 140˚C (284˚F) (internal).

PC - Protection Coil

Purpose

For applications where the hose requires protection against abrasion when dragged over the ground, but where any rubber reinforcement is not permissible due to temperature, chemicals etc.

Design

A stainless steel wire helix is wound onto the braid and welded to the ferrules at each end.

Limitations

Available for all sizes and grades of hose, including rubber covered.

The maximum assembly lengths for all sizes are capped at 20 metres (65 feet).

Specifications

As for the relevant hose grade.

Non-lined Fittings

Flange Specification

- ANSI B16.5 (also ASME B16.5) Class 150# and 300#

- *DIN PN10/16/40 up to 2” size, PN10/16 from 21/2 ” up to 6” size

- JIS 10K

- Other Pressure Ratings and Flange Specifications are also available

*The dimensions for flanges to the different pressure ratings are identical, so they are inter-changeable.

Maximum Pressure Ratings for Flange Fittings

- ANSI 150# = 16 Bar (230 psi), ANSI 300# = 32 Bar (460 psi)

- DIN PN10 = 10 Bar (145 psi), DIN PN16 = 16 Bar (230 psi), DIN PN40 = 40 Bar (580psi)

End Fitting Materials

- Flanges in Grade 304 SS

- Flange Retainers in Grade 316L SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316 SS

Alternative Options for Flange Component only:

- Zinc Plated Carbon Steel

- Grade 316 Stainless Steel

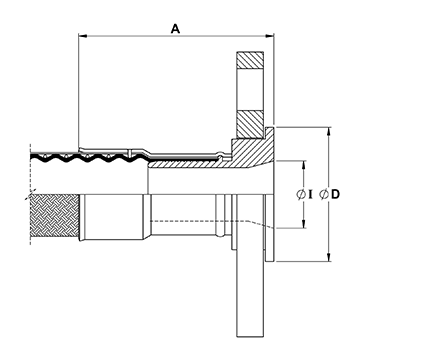

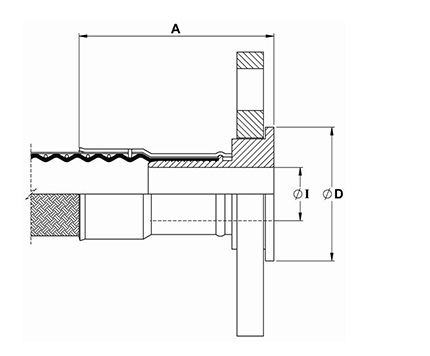

The above drawing relates to sizes 1", 11/2 ", 2"

The above drawing relates to all other sizes

| Nominal Hose Size |

*Fitting Length A

PN |

Flared Diameter D

PN/10/16 |

Fitting Inside Diameter I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

2.20 |

56 |

1.77 |

45 |

0.39 |

10 |

0.76 |

1.69 |

| 3/4 |

20 |

3.11 |

79 |

2.28 |

58 |

0.63 |

16 |

1.06 |

2.35 |

| 1 |

25 |

3.46 |

88 |

2.68 |

68 |

1.12 |

28.5 |

1.36 |

3.00 |

| 1 1/4 |

32 |

3.98 |

101 |

3.07 |

78 |

1.02 |

26 |

1.72 |

3.79 |

| 1 1/2 |

40 |

4.69 |

119 |

3.46 |

88 |

1.69 |

43.10 |

2.49 |

5.50 |

| 2 |

50 |

4.69 |

119 |

4.02 |

102 |

2.15 |

54.5 |

3.57 |

7.87 |

| 2 1/2 |

65 |

5.20 |

132 |

4.80 |

122 |

2.24 |

57 |

4.20 |

9.26 |

| 3 |

80 |

5.28 |

134 |

5.43 |

138 |

2.64 |

67 |

5.68 |

12.52 |

| 4 |

100 |

5.51 |

140 |

6.22 |

158 |

3.50 |

89 |

8.42 |

18.56 |

| 6 |

150 |

7.00 |

178 |

8.35 |

212 |

5.51 |

140 |

12.30 |

27.12 |

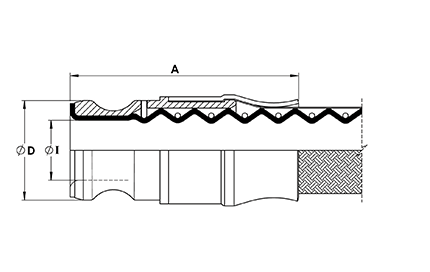

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP)

| Nominal Hose Size |

*Fitting Length A

ASA |

Flared Diameter D

ASA150 |

Fitting Inside Diameter I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

2.13 |

54 |

1.37 |

34.9 |

0.39 |

10 |

0.76 |

1.69 |

| 3/4 |

20 |

2.99 |

76 |

1.69 |

42.9 |

0.63 |

16 |

1.06 |

2.35 |

| 1 |

25 |

2.95 |

75 |

2.00 |

50.8 |

0.79 |

20.24 |

1.36 |

3.00 |

| 1 1/4 |

32 |

3.78 |

96 |

2.50 |

63.5 |

1.02 |

26 |

1.72 |

3.79 |

| 1 1/2 |

40 |

4.25 |

108 |

2.87 |

73.0 |

1.25 |

31.75 |

2.49 |

5.50 |

| 2 |

50 |

4.41 |

112 |

3.63 |

92.1 |

1.75 |

44.45 |

3.57 |

7.87 |

| 2 1/2 |

65 |

5.27 |

134 |

4.12 |

104.5 |

2.24 |

57 |

4.20 |

9.26 |

| 3 |

80 |

5.43 |

138 |

5.00 |

127.0 |

2.64 |

67 |

5.68 |

12.52 |

| 4 |

100 |

5.51 |

140 |

6.19 |

157.2 |

3.50 |

89 |

8.42 |

18.56 |

| 6 |

150 |

7.00 |

178 |

8.50 |

215.9 |

5.51 |

140 |

12.30 |

27.12 |

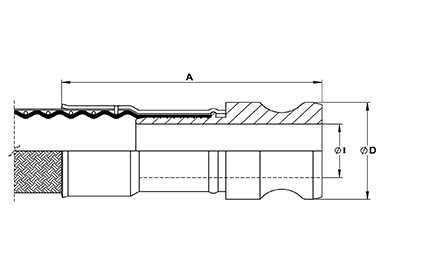

PTFE lined Fittings

Flange Specification

- ANSI B16.5 (also ASME B16.5) Class 150# and 300#

- *DIN PN10/16/40 up to 2” size, PN10/16 from 21/2 ” up to 6” size

- JIS 10K

- Other Pressure Ratings and Flange Specifications are also available

*The dimensions for flanges to the different pressure ratings are identified, so they are inter-changeable.

Maximum Pressure Ratings for Flange Fittings

- ANSI 150# = 16 Bar (230 psi), ANSI 300# = 32 Bar (460 psi)

- DIN PN10 = 10 Bar (145 psi)

- DIN PN16 = 16 Bar (230 psi), DIN PN40 = 40 Bar (580psi)

End Fitting Materials

- Flanges in Grade 304 SS

- Flange Retainers in Grade 316L SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

Alternative options for Flange component only:

- Zinc Plated Carbon Steel

- Grade 316 Stainless Steel

90˚ Elbow Flange Fittings

90˚ Elbow Integral PTFE lined Flange Fittings are available for 1”, 11/2” & 2”.

Nominal Size -

Flange & Hose |

*Fitting Length A

ASA |

*Fitting Length A

PN |

Flared Diameter D |

Recommended Bolt

Tightening Torques |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

ASA 150

mm |

PN/10/16

mm |

ft.lbs |

Nm |

Kg |

Lbs |

| 1/2 |

15 |

2.09 |

53 |

2.09 |

53 |

32.0 |

32.0 |

8 |

10.79 |

0.54 |

1.19 |

| 3/4 |

20 |

2.28 |

58 |

2.34 |

59.5 |

43.0 |

50.0 |

8 |

10.79 |

0.88 |

1.94 |

| 1 |

25 |

2.28 |

58 |

2.36 |

60 |

50.8 |

63.5 |

10 |

13.73 |

0.96 |

2.11 |

| 11/4 |

32 |

2.48 |

63 |

2.52 |

64 |

63.0 |

78.0 |

12 |

16.67 |

1.36 |

2.99 |

| 11/2 |

40 |

2.40 |

61 |

2.50 |

63.5 |

73.0 |

88.0 |

15 |

20.59 |

1.75 |

3.85 |

| 2 |

50 |

2.52 |

64 |

2.62 |

66.5 |

92.0 |

102.0 |

25 |

34.32 |

2.70 |

5.94 |

| 21/2 |

65 |

3.11 |

79 |

3.19 |

81 |

105.0 |

122.0 |

30 |

41.18 |

4.00 |

8.80 |

| 3 |

80 |

3.11 |

79 |

3.11 |

79 |

127.0 |

127.0 |

40 |

53.94 |

5.00 |

11.00 |

| 4 |

100 |

5.20 |

132 |

5.20 |

132 |

158.0 |

158.0 |

40 |

53.94 |

7.00 |

15.40 |

| 6 |

150 |

3.66 |

93 |

3.66 |

93 |

213.0 |

213.0 |

50 |

67.67 |

13.00 |

29.00 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

‘Step-Up’ PTFE Lined Flange Fitting Design for Corroflon Hose

Adapting for Different Flange Sizes

To fit larger than nominal flange sizes

It may be necessary to fit a larger than nominal flange size to the hose - for example, 3” flange fitted to one end of a 2” hose - in which case it may also be necessary to increase the diameter of the sealing face to the correct size for the larger flange. This can be achieved by means of a flange adaptor as shown.

To fit smaller than nominal flange sizes

Within limits, it is also possible to make up an assembly with a flange one size smaller than the nominal size. The smaller flange is bored out and fitted to the larger hose and, if necessary, the flared diameter is reduced to suit.

Consult the supplier if a different flange size is required.

Female Fittings

End Fitting Specification

- Generally in accordance with A-A-59326 (replaces MIL-C-27487) and EN14420-1 (replaces DIN 2828), and all are fully interchangeable.

Temperature and Pressure Ratings

- When used with a Buna N Gasket all sizes up to 16 Bar (230 psi) and up to a maximum temperature of 65˚C (149˚F).

- When used with FEP, Fluoro Rubber or other encapsulated gaskets all sizes up to 10 Bar (145 psi) and up to a maximum temperature of 204˚C (400˚F).

End Fitting Materials

- Spigot in Grade 316L SS

- Body in Grade 316C SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

- Standard Gasket is Buna N (Nitrile) Rubber.

- FEP encapsulated Silicone Rubber Gaskets also available.

90˚Elbow Cam & Groove Fittings (Lined Only)

- 90˚ Elbow Integral PTFE lined Cam & Groove Fittings are available for sizes 1”, 11/2 ” and 2”.

Swivelling, Locking Arm Female Cam and Groove Fittings - Non Lined

| Nominal Hose Size |

*Fitting Length A |

Cam Sleeve Inside Diameter D |

Fitting Inside Diameter I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 3/4 |

20 |

3.11 |

79 |

1.26 |

32 |

0.63 |

15.9 |

0.40 |

0.88 |

| 1 |

25 |

3.07 |

78 |

1.46 |

37 |

0.75 |

19.1 |

0.51 |

1.12 |

| 11/2 |

40 |

4.13 |

105 |

2.13 |

54 |

1.25 |

31.8 |

0.88 |

1.94 |

| 2 |

50 |

4.25 |

108 |

2.52 |

64 |

1.75 |

44.5 |

1.15 |

2.53 |

| 21/2 |

65 |

4.49 |

114 |

3.03 |

77 |

2.25 |

57.2 |

1.41 |

3.10 |

| 3 |

80 |

4.61 |

117 |

3.62 |

92 |

2.63 |

66.7 |

1.89 |

4.17 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

Fixed, Locking Arm Female Cam and Groove Fitting - Integral PTFE Lined

| Nominal Hose Size |

*Fitting Length A |

Cam Sleeve Inside Diameter D |

Fitting Inside Diameter I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 3/4 |

20 |

2.48 |

63 |

1.26 |

32 |

0.70 |

17.8 |

0.39 |

0.86 |

| 1 |

25 |

2.40 |

61 |

1.46 |

37 |

0.95 |

24.1 |

0.50 |

1.10 |

| 11/2 |

40 |

2.56 |

65 |

2.13 |

54 |

1.44 |

36.7 |

0.86 |

1.89 |

| 2 |

50 |

2.56 |

65 |

2.52 |

64 |

1.94 |

49.3 |

1.10 |

2.42 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

Notes: For Integral PTFE Lined Fittings Only

FEP Gaskets require higher clamping forces to flatten the Seal and make the joint. This is made easier by ‘pre-setting’ these gaskets by clamping Polypropylene Cam Male Inserts to the assembled fittings, which must then be kept in place during storage, until use.

Any Customer’s Own ‘Special’ Gaskets must be pre-supplied to Aflex for special assembly and testing of hose assemblies, to ensure suitability.

Male Fittings

End Fitting Specification

- Generally in accordance with A-A-59326 (replaces MIL-C-27487) and EN14420-1 (replaces DIN 2828), and all are fully interchangeable.

Temperature and Pressure Ratings

- Temperature and pressure determined by the type of gasket in the Female connecting component.

End Fitting Materials

- Fittings in Grade 316L SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

- Adaptor Flange Only in Grade 304 SS

Integral PTFE Lined Cam & Groove Male Fitting

Non-Lined Cam & Groove Male Fitting

| Nominal Hose Size |

øD |

Fitting Length A |

Non-Lined Inside

Diameter I |

Lined Inside

Diameter B |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 3/4 |

20 |

1.26 |

32 |

3.38 |

86 |

0.63 |

15.88 |

0.70 |

17.78 |

0.40 |

0.88 |

| 1 |

25 |

1.46 |

37 |

3.66 |

93 |

0.80 |

20.24 |

0.88 |

22.35 |

0.49 |

1.08 |

| 11/2 |

40 |

2.13 |

54.0 |

5.00 |

127 |

1.25 |

31.75 |

1.12 |

28.50 |

0.81 |

1.78 |

| 2 |

50 |

2.52 |

64 |

5.67 |

144 |

1.75 |

44.45 |

1.77 |

44.96 |

1.05 |

2.31 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

PTFE Lined Male Cam and Groove X Flange Adaptors

Cam Action

Adaptor Size |

Flange Size &

Specification |

øD |

A |

I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1 |

25 |

1"ANSI/1507 |

2.00 |

50 |

4 1/8 |

105 |

0.84 |

21 |

1.246 |

2.75 |

| 1 |

25 |

DN25/PN16 |

2.58 |

64 |

4 1/8 |

105 |

0.84 |

21 |

1.538 |

3.39 |

| 1 1/2 |

40 |

11/2"ANSI/1507 |

2.87 |

73 |

4 3/8 |

118 |

1.35 |

34 |

2.228 |

4.92 |

| 1 1/2 |

40 |

DN40/PN16 |

3.47 |

88 |

4 3/4 |

118 |

1.35 |

34 |

2.753 |

6.07 |

| 2 |

50 |

2" ANSI/1507 |

3.63 |

92 |

4 3/4 |

118 |

1.69 |

43 |

3.359 |

7.40 |

| 2 |

50 |

DN50/PN16 |

4.02 |

102 |

4 3/4 |

118 |

1.69 |

43 |

3.714 |

8.19 |

Note: Other Flange Specifications and Pressure Ratings are also available. Non-Lined adaptors and Female Cam and Groove X Flange Adaptors are also available, to special order.

PTFE lined & flared Fittings

End Fitting Specification

- BS4825 Pt 3 (UK)

- ASME BPE-a-2007 (USA)

- DIN32676 (Europe, DN Sizes)

- ISO 1127 (Europe) (Non Standard, Specials Only)

Temperature and Pressure Ratings

- Pressures up to 16 Bar (230 psi)

- Temperatures up to 180˚C (356˚F)

- Higher Pressures & Temperatures possible with Special Clamps and appropriate Seals.

End Fitting Materials

- Fittings in Grade 316L SS (= BS 316 S11 = EN 1.4404)

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

90˚ Elbows

PTFE Lined 90˚ elbow fittings are available for some sizes and grades

| Nominal Hose Size |

Nominal Pipe Size |

Outlet Diameter I |

Flange Diameter D |

*Length of Fitting A |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

15 |

1/2 |

12.7 |

3/8 |

9.5 |

0.984 |

25.0 |

1.96 |

50 |

0.075 |

0.17 |

| 1 |

25 |

1 |

25.4 |

7/8 |

22.2 |

1.984 |

50.5 |

2.36 |

60 |

0.226 |

0.50 |

| 1 1/2 |

40 |

11/2 |

38.1 |

13/8 |

34.9 |

1.984 |

50.5 |

2.48 |

63 |

0.269 |

0.59 |

| 2 |

50 |

2 |

50.8 |

17/8 |

47.6 |

2.516 |

64.0 |

2.60 |

66 |

0.407 |

0.90 |

| 2 1/2 |

65 |

21/2 |

63.4 |

23/8 |

60.3 |

3.050 |

77.5 |

3.22 |

82 |

0.510 |

1.12 |

| 3 |

80 |

3 |

76.1 |

27/8 |

73.0 |

3.580 |

91.0 |

3.22 |

82 |

0.593 |

1.30 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

Non-lined Fittings

End Fitting Specification

- BS4825 Pt 3 (UK)

- ASME BPE-a-2007 (USA)

- DIN32676 (Europe, DN Sizes)

- ISO 1127 (Europe) (Non Standard, Specials Only)

Temperature and Pressure Ratings

For Standard Clamp and Standard (EPDM) Gasket

- Pressures up to 16 Bar (230 psi)

- Temperatures up to 120˚C (250˚F)

- Higher Pressures and Temperatures with Special Clamps and Gaskets

End Fitting Materials

- Fittings in AISI 316L = EN 1.4404 = BS 316 S11. Internal Bores all Electropolished to <15µin Ra (<0.375µ mtr).

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

Outlet Diameters (Inch pipe sizes only)

The outlet diameters as listed are in accordance with BS4825. The ASME specification, however, requires these diameters to be 0.005” (0.125mm) less in each case. An Outlet Diameter tolerance of +0.000 -0.005” has therefore been applied, so that the same fitting satisfies requirements of both specifications.

Mini-sanitary Triclamp (triclover) Fittings

| Nominal Hose Size |

Nominal Pipe Size |

*Fitting Length A |

Flange Dia. D |

Outlet Dia. I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2" |

1/2" & DN10 |

2.13 |

54 |

0.984 |

25.0 |

3/8 |

9.5 |

0.05 |

0.11 |

| 1/2" |

3/4" |

2.13 |

54 |

0.984 |

25.0 |

5/8 |

16.0 |

0.04 |

0.09 |

| 3/4" |

3/4" |

3.03 |

77 |

0.984 |

25.0 |

5/8 |

16.0 |

0.05 |

0.11 |

Sanitary Triclamp (triclover) Fitting

| Nominal Hose Size |

Nominal Pipe Size |

*Fitting Length A |

Flange Dia. D |

Outlet Dia. I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2" |

1" |

2.01 |

51 |

1.984 |

50.5 |

7/8 |

22.2 |

0.13 |

0.28 |

| 3/4" |

DN15 |

2.96 |

75 |

1.156 |

34.0 |

5/8 |

16.0 |

0.12 |

0.26 |

| 3/4" |

ISO (DN) 15 |

2.96 |

75 |

1.984 |

50.5 |

0.713 |

18.10 |

0.16 |

0.35 |

| 3/4" |

ISO (DN) 20 |

2.96 |

75 |

1.984 |

50.5 |

0.934 |

23.7 |

0.15 |

0.33 |

| 1" |

1" |

3.39 |

86 |

1.984 |

50.5 |

7/8 |

22.2 |

0.25 |

0.54 |

| 1" |

DN25 |

3.39 |

86 |

1.984 |

50.5 |

1 |

26.0 |

0.24 |

0.52 |

| 1" |

ISO (DN) 25 |

3.39 |

86 |

1.984 |

50.5 |

1.170 |

29.7 |

0.23 |

0.52 |

| 1" |

1 1/2" |

3.39 |

86 |

1.984 |

50.5 |

1 3/8" |

34.9 |

0.22 |

0.48 |

| 1 1/2" |

1 1/2" |

4.02 |

102 |

1.984 |

50.5 |

1 3/8" |

34.9 |

0.27 |

0.59 |

| 1 1/2" |

DN40 |

4.02 |

102 |

1.984 |

50.5 |

1 1/2" |

38.0 |

0.25 |

0.56 |

| 2" |

2" |

4.02 |

108 |

2.516 |

64.0 |

1 7/8" |

47.6 |

0.39 |

0.86 |

| 2" |

DN50" |

4.25 |

108 |

2.516 |

64.0 |

1.975 |

50.0 |

0.37 |

0.82 |

| 2" |

2 1/2" |

4.13 |

105 |

3.047 |

77.5 |

2 3/8" |

60.3 |

0.42 |

0.92 |

| 2" |

DN65 |

4.13 |

105 |

3.047 |

77.5 |

2.600 |

66.0 |

0.40 |

0.88 |

| 2" |

3" |

4.53 |

115 |

3.579 |

91.0 |

2 7/8" |

73.0 |

0.68 |

1.50 |

| 2" |

DN80 |

4.53 |

115 |

4.176 |

106.0 |

3.191 |

81.0 |

1.12 |

2.47 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

90° Elbow Fitting

End Fitting Specification

- BS4825 Pt 3

- ASME-BPE-a

- Others to Special Order

Temperature and Pressure Ratings

For Standard Clamp and Standard (EPDM) Gasket

- Pressures up to 16 Bar (230 psi)

- Temperatures up to 120˚C (250˚F)

- Higher Pressures and Temperatures with Special Clamps and Gaskets.

End Fitting Materials

- Fittings in Grade AISI 316L = EN 1.4404 = BS 316 S11

- Internal Bore average 15µin Ra, Electropolished if required

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

Outlet Diameters

The outlet diameters as listed are in accordance with BS4825. The ASME specification, however, requires these diameters to be 0.005” (0.125mm) less in each case. An Outlet Diameter tolerance of +0.000 -0.005” has therefore been applied, so that the same fitting satisfies requirements of both specifications.

| Nominal Hose Size |

*Centre Line To Fitting End A |

Centre Line to Face B |

Flange Diameter D |

*Outlet Diameter I |

Weight of Fitting |

| in |

mm |

in |

mm |

mm |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

5.78 |

147 |

1.60 |

41.0 |

0.984 |

25.0 |

3/8 |

9.5 |

0.137 |

0.30 |

| 3/4 |

20 |

6.41 |

163 |

1.60 |

41.0 |

0.984 |

25.0 |

5/8 |

16.0 |

0.205 |

0.45 |

| 1 |

25 |

6.53 |

166 |

2.00 |

51.0 |

1.984 |

50.5 |

7/8 |

22.2 |

0.347 |

0.77 |

| 11/2 |

40 |

7.99 |

203 |

2.75 |

70.0 |

1.984 |

50.5 |

13/8 |

34.9 |

0.590 |

1.30 |

| 2 |

50 |

9.33 |

237 |

3.50 |

88.9 |

2.519 |

64.0 |

17/8 |

47.6 |

0.928 |

2.05 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

DIN 11851 Fittings

Description

- DIN 11851 male and female fittings, integrally PTFE lined.

- Also available non-lined, up to 4” (100mm), to special order.

Specification

- Generally to German DIN 11851 specification.

Note: The PTFE lined male fitting is designed to be used without a rubber seal. Please note that when connecting to a PTFE Lined DIN11851 Male, extra spanner tightening of the nut is sometimes required in order to provide a leak free connection.

End Fitting Materials

- Spigots in Grade 316L SS

- Nuts in Grade 304 SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

Temperature & Pressure Ratings

- Sizes up to 11/2” MWP = 40 Bar (580 psi) up to 140˚C (284˚F)

- Sizes 2” to 3” MWP = 25 Bar (360 psi) up to 140˚C (284˚F)

Except where the applicable hose pressure/temperature ratings are lower.

90˚ Elbows

PTFE Lined 90˚ elbow fittings are available for some sizes and grades.

DIN11851 Female Fitting

DIN11851 Male Fitting

| Nominal Hose Size |

*Fitting Length A (Male) |

*Fitting Length A (Female) |

Weight of Fitting |

| Male |

Female |

| in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

Kg |

Lbs |

| 3/4 |

20 |

23/8 |

60 |

23/8 |

60 |

0.18 |

0.39 |

0.22 |

0.48 |

| 1 |

25 |

23/8 |

60 |

25/8 |

67 |

0.22 |

0.48 |

0.36 |

0.79 |

| 11/4 |

32 |

21/2 |

65 |

23/4 |

70 |

0.27 |

0.59 |

0.47 |

1.04 |

| 11/2 |

40 |

25/8 |

67 |

27/8 |

73 |

0.33 |

0.73 |

0.55 |

1.21 |

| 2 |

50 |

25/8 |

67 |

27/8 |

73 |

0.58 |

1.28 |

0.93 |

2.05 |

| 21/2 |

65 |

31/2 |

89 |

35/8 |

92 |

0.73 |

1.61 |

1.31 |

2.88 |

| 3 |

80 |

4 |

100 |

35/8 |

92 |

1.00 |

2.20 |

1.57 |

3.46 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

DIN11851 Female Fittings, not PTFE Lined

Description

DIN11851 Female Fittings, Non-Lined, are available in sizes 3/4”, 1”, 11/2”, 2”, 21/2”, 3” and 4”. Consult Aflex Hose for details.

Materials

Spigots in Grade 1.4571 (AISI 316 T), Nuts in Grade 304 SS, Ferrules, most in Grade 304 SS, some in Grade 316 SS.

| Nominal Hose Size |

ID (I) |

Fitting Length (A) |

Fitting Weight |

| in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

16 |

0.63 |

48 |

1.89 |

0.18 |

0.40 |

| 3/4 |

20 |

20 |

0.79 |

73 |

2.87 |

0.24 |

0.53 |

| 1 |

25 |

26 |

1.02 |

74 |

2.91 |

0.41 |

0.90 |

| 11/4 |

32 |

32 |

1.26 |

89 |

3.50 |

0.52 |

1.15 |

| 11/2 |

40 |

38 |

1.50 |

101 |

3.98 |

0.75 |

1.65 |

| 2 |

50 |

50 |

1.97 |

105 |

4.13 |

1.11 |

2.45 |

SMS & RJT Female Fittings

End Fitting Specification

- SMS generally to Swedish SMS1148 specification.

- RJT generally to British BS4825 Pt 5 specification.

Temperature and Pressure Ratings

- Pressures up to 10 Bar (150 psi)

- Temperatures up to 150˚C (302˚F)

End Fitting Materials

- Spigots in Grade 316L SS

- Nuts in Grade 304 SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

90˚ Elbows

PTFE Lined 90˚ elbow fittings are available for some sizes and grades.

SMS Female Fittings

| Nominal Size |

*Length A |

Outlet Dia. I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1 |

25 |

31/8 |

79 |

1 |

25 |

0.60 |

1.32 |

| 11/2 |

40 |

31/2 |

89 |

11/2 |

38 |

0.98 |

2.16 |

| 2 |

50 |

33/4 |

95 |

2 |

50 |

1.22 |

2.69 |

| 21/2 |

65 |

45/8 |

116 |

21/2 |

63 |

1.549 |

3.41 |

| 3 |

80 |

43/4 |

122 |

3 |

75 |

1.997 |

4.40 |

RJT Female Fittings

| Nominal Size |

*Length A |

Outlet Dia. I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1 |

25 |

2.68 |

68 |

0.80 |

20.24 |

0.27 |

0.6 |

| 11/2 |

40 |

3.78 |

96 |

1.25 |

31.75 |

0.49 |

1.08 |

| 2 |

50 |

3.90 |

99 |

1.75 |

44.45 |

0.67 |

1.48 |

| 21/2 |

65 |

4.09 |

104 |

2.25 |

57.15 |

0.78 |

1.72 |

| 3 |

80 |

4.21 |

107 |

2.63 |

66.7 |

0.89 |

1.96 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

NPT and BSPT Fittings

End Fitting Specification

- NPT Taper Threads to American National Standard Pipe Taper Thread design to ANSI/AMSE B1.20.1

- BSPT Threads to British Standard Pipe Taper Thread design to BS21

Alternatives - Parallel Threads, Metric Threads and Others.

End Fitting Materials

- Fittings in Grade 316L SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

Alternatives - Fittings in Zinc Plated Carbon Steel

Fixed Male NPT or BSPT

| Nominal Hose Size |

*Fitting Length A |

Inside Diameter I |

Weight of Fitting |

| in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

15 |

25/8 |

67 |

0.38 |

9.53 |

0.10 |

0.22 |

| 3/4 |

20 |

31/2 |

89 |

0.63 |

15.88 |

0.18 |

0.40 |

| 1 |

25 |

37/8 |

98 |

0.80 |

20.24 |

0.29 |

0.64 |

| 11/4 |

32 |

43/8 |

110 |

1.03 |

26.21 |

0.45 |

0.99 |

| 11/2 |

40 |

51/8 |

130 |

1.25 |

31.75 |

0.60 |

1.32 |

| 2 |

50 |

51/2 |

140 |

1.75 |

44.45 |

0.84 |

1.85 |

| 21/2 |

65 |

63/4 |

170 |

2.25 |

57.15 |

1.70 |

3.75 |

| 3 |

80 |

63/4 |

170 |

2.63 |

66.70 |

2.53 |

5.58 |

| 4 |

100 |

71/2 |

190 |

3.50 |

88.90 |

3.99 |

8.80 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

Fixed Female NPT

| Nominal Hose Size |

NPT or BSPT Thread Size |

*Fitting Length A |

Fitting Inside Diameter I |

Weight of Fitting |

| in |

mm |

in |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

1/2 |

2.72 |

69 |

0.38 |

9.53 |

0.18 |

0.40 |

| 3/4 |

20 |

3/4 |

3.54 |

90 |

0.63 |

15.88 |

0.22 |

0.49 |

| 1 |

25 |

1 |

3.82 |

97 |

0.80 |

20.24 |

0.33 |

0.73 |

| 11/2 |

40 |

1 1/2 |

4.96 |

126 |

1.25 |

31.75 |

0.75 |

1.65 |

| 2 |

50 |

2 |

5.16 |

131 |

1.75 |

44.45 |

1.06 |

2.34 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

BSP 60° Cone Seat Female Fittings

End Fitting Specification

- BSPP Threads to British Standard Pipe Parallel Thread design to BS21, 60˚ Cone Seat design, or Flat Seat.

- Available in sizes up to 4"

Alternatives - Cone Seat Female Union Fittings can be supplied with a BSPP/BSPT Taper Male Adaptor if required.

End Fitting Materials

- Spigots in Grade 316L SS

- Nuts in Grade 316L SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

Alternatives

- Cone Seat Female Unions can be supplied in Zinc Plated Carbon Steel if required.

- Lug Nuts can be supplied in Gun Metal (Bronze) if required.

BSP 60˚ Cone Seat Female Union Fitting

| Nominal Hose Size |

NPT or BSPT

Thread Size |

*Fitting Length A |

Fitting Inside

Diameter I |

Weight of Fitting |

| in |

mm |

in |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

1/2 |

21/2 |

63 |

0.37 |

9.35 |

0.11 |

0.25 |

| 3/4 |

20 |

3/4 |

31/2 |

89 |

0.63 |

15.88 |

0.15 |

0.34 |

| 1 |

25 |

1 |

31/2 |

89 |

0.80 |

20.24 |

0.24 |

0.53 |

| 11/2 |

40 |

11/2 |

37/8 |

98 |

1.25 |

31.75 |

0.72 |

1.59 |

| 2 |

50 |

2 |

4 |

100 |

1.75 |

44.45 |

0.99 |

2.19 |

BSP Flat Face Lug Nut Female Fitting

| Nominal Hose Size |

BSPP Thread Size |

*Fitting Length A |

Fitting Bore Diameter I |

Weight of Fitting |

| in |

mm |

in |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1 |

25 |

1 |

2.72 |

69 |

0.80 |

20.24 |

0.25 |

0.55 |

| 1 1/2 |

40 |

1 1/2 |

3.78 |

96 |

1.25 |

31.75 |

0.61 |

1.33 |

| 2 |

50 |

2 |

3.90 |

99 |

1.75 |

44.45 |

0.88 |

1.95 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP)

JIC Fittings

End Fitting Specification

- SAE J514 37˚ Flare JIC Female Fitting

- 37˚ JIC Male-to-NPT Male/Female Adaptors

- NPT Threads to ANSI B2.1

Temperature and Pressure Ratings

Same Maximum Working Pressure and Temperature as for the relevant size of Corroflon Hose, in Specifications & Properties.

End Fitting Materials

- Spigots in Grade 316L SS

- Nuts in 316L SS

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

Note - Not usable with SAE 45˚ Flare fittings which have the same thread.

Alternatives - Can be supplied in other materials, such as zinc plated carbon steel, Hastelloy, Monel etc.

| Nominal Hose Size |

37˚ JIC Thread Size |

*Fitting Length A |

Hex Size

H |

Fitting Inner

Diameter I |

Weight of Fitting |

| in |

mm |

in |

in |

mm |

in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

3/4 - 16 |

2.13 |

54 |

0.88 |

22.2 |

0.38 |

9.5 |

0.11 |

0.24 |

| 3/4 |

20 |

1 1/16 - 12 |

2.99 |

76 |

1.25 |

31.7 |

0.63 |

15.9 |

0.15 |

0.34 |

| 1 |

25 |

1 5 /16 - 12 |

3.66 |

93 |

1.50 |

38.1 |

0.80 |

20.2 |

0.23 |

0.52 |

| 1 1/2 |

40 |

1 7/8-12 |

4.17 |

106 |

2.25 |

57.1 |

1.25 |

31.7 |

0.72 |

1.58 |

| 2 |

50 |

2 1/2 - 12 |

4.49 |

114 |

2.88 |

73.0 |

1.75 |

44.4 |

0.99 |

2.18 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

JIC to NPT Male Union (Including a JIC male-to-NPT male adaptor)

| Nominal Hose Size |

*Male Union Length A1 |

Weight of Fitting |

| in |

mm |

in |

mm |

Kg |

Lbs |

| 1/2 |

13 |

4.13 |

105 |

0.22 |

0.48 |

| 3/4 |

20 |

4.93 |

125 |

0.33 |

0.72 |

| 1 |

25 |

5.43 |

138 |

0.52 |

1.15 |

JIC to NPT Female Union (Including a JIC Male to NPT Female Adaptor)

| *Female Union Length A2 |

Fitting Inner Diameter I |

Weight of Fitting |

| in |

mm |

in |

mm |

Kg |

Lbs |

| 3.26 |

92 |

0.38 |

9.5 |

0.21 |

0.47 |

| 4.80 |

122 |

0.63 |

15.9 |

0.33 |

0.74 |

| 5.35 |

136 |

0.80 |

20.2 |

0.68 |

1.50 |

*Fitting Lengths listed are for Corroflon braided only hose grades (SS, PB, HB, KYB). Approximately 33% longer lengths apply to the rubber covered hose grades (RC, SI, FP).

PTFE Dip Pipe Fittings

Fixed Dip Pipes

Description

Fixed Dip Pipes are fairly rigid, thick wall PTFE tubes, either straight or 90˚ elbowed, which are directly crimped to the end of Corroflon hoses. They are designed for insertion into drums, tanks and reaction vessels in order to suction drain (or inject) process fluids transferred through the hose.

Materials

- Standard dip pipes are in anti-static (AS) PTFE

- Ferrules, most in Grade 304 SS, some sizes in Grade 316L SS

How to order

Specify the size and material of the dip pipe, whether it is straight or 90˚ elbowed. Give the length of the straight leg of the dip pipe and the length of the rest of the hose assembly separately.

Maximum Working Pressures

Dip Pipes are normally only tested to 6 Bar Pressure, and are not suitable for use at pressures higher than 3 Bar. They are usable atnegative pressure up to -0.9bar vacuum.

If higher pressure ratings are required, consult Aflex Hose.

Lengths

Dip Pipes are supplied as standard in 1 metre straight lengths, but can be supplied in any length to individual requirements.

Fixed Dip Pipe (90˚ Elbow)

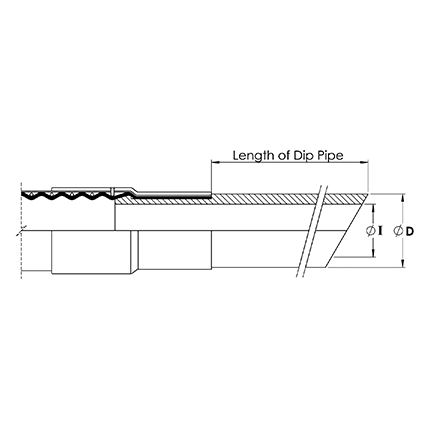

Fixed Dip Pipe (Straight)

| Approximate Dip Pipe Dimensions |

| Nominal Hose Bore Size |

Outside Diameter D |

Inside Diameter |

| in |

mm |

in |

mm |

in |

mm |

| 3/4 |

20 |

0.87 |

22 |

0.51 |

13 |

| 1 |

25 |

1.14 |

29 |

0.83 |

21 |

| 1 1/2 |

40 |

1.54 |

39 |

1.00 |

27 |

| 2 |

50 |

2.17 |

55 |

1.58 |

40 |

Detachable Dip Pipes

Description

As Fixed Dip Pipes above, but connected to the hose through an end fitting, not by crimping direct to the hose.

Design

A straight, or 90˚ elbowed anti-static PTFE Dip Pipe, fitted with a Flange or Cam & Groove Male PTFE Lined & Flared end fitting.

The most usual end fitting is a Cam Male (as shown), so the dip pipe can then be connected to a hose with a Cam Female end fitting.

Specifications

As above for Fixed Dip Pipes.

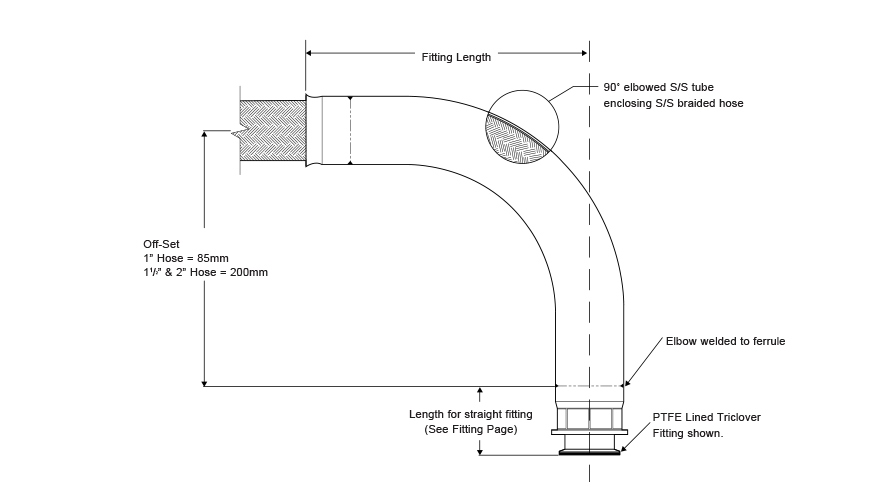

90° Elbow Fittings

PTFE Lined 90˚ Elbow Fittings

Scope

- All of the PTFE lined end fittings described on previous pages can be fitted as 90˚ elbow PTFE lined fittings to the design shown, to the sizes listed.

- All grades of hose can be used, except PB and KYB.

| Hose Bore Sizes |

Off-Set |

Fitting Length |

Weight of Fitting |

| mm |

mm |

Kg |

Lbs |

| 1" |

85 |

143 |

0.48 |

1.07 |

| 1 1/2" |

200 |

237 |

1.37 |

3.03 |

| 2" |

200 |

314 |

1.68 |

3.70 |

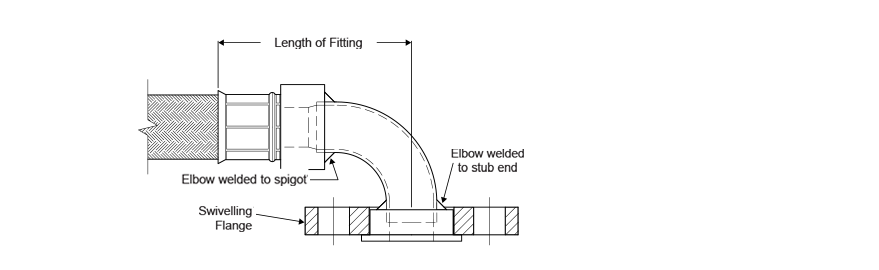

Non-Lined 90˚ Elbow Fittings

A 90˚ elbow attached to the hose can be supplied non-PTFE lined, as shown, for any size or grade of hose or type of fittings, to special order.

Labeling & Color Coding

Standard Labeling

All Corroflon hose assemblies are labelled with the following information:

- Manufacturer’s Name

- Hose Size and Grade

- EN16643 and Year of Standard Publication

- EN16643 Electrical Property Grade

- Max. Working Pressure and Test Pressure

- Working Temperature Range*

- Unique Serial Number

- Month & Year of Manufacture

- Telephone Number

- CE Mark (if applicable)

*Note any restrictions on working pressure resulting from elevated temperatures

This information is normally laser-etched on to a loose stainless steel Ring mounted on the hose.

In some cases, at the discretion of Aflex Hose, the information may be etched on to a thin stainless steel plate which is clamped to the hose, or on to the end fitting ferrule at one end. This may be necessary for example, if the customer requires additional information which may not fit on to a Ring.

Customers may specify which labelling system they require, and may request additional information on the label.

Streamline Tagging

This system is only applicable to the Silicone (SI) rubber covered grades of Corroflon that have a stainless steel (SS) braid.

A label and/or Color Code is placed around the silicone cover of the hose and then encapsulated by a transparent silicone that is formed into a thin streamlined cover.

Note: 1/2” size, Color Code only, no text.

Color Coding

This system is applicable to all grades of Corroflon hose.

A coloured PTFE spiral strip is wound on to the hose. It can be left loose, or it can be encapsulated under a transparent, heat-shrunk polyolefin sleeve.

How to Order

The quantity, hose size, liner, braid, cover, protection system, length and fittings must be selected and specified in full.

EITHER by a full, written description. The hose grade can be specified by the code initials e.g. “Corroflon AS, SS, RC, DRC-300” defines an antistatic PTFE lined hose with an EPDM rubber cover over a SS braid, with a double rubber cover at both ends.

The quantity, length and fittings can then be written in - e.g. “4 off x 1” bore Corroflon, AS, SS, RC, DRC-300 hose x 3.00 metres long (10ft). Both ends non-lined ANSI 150# S/S Flanges”.

OR by Part Numbers.

Any special requirements relating to the hose construction, or information required on Tags, or Certificates, or special testing of requirements, must be specified in full on the enquiry or purchase order.

Selecting the Hose Grade

PTFE Liners include, Standard (GP) or Special Purpose (SP), both available either in natural white PTFE or in black, Antistatic PTFE (AS). There are four types of braid, Grade 304 stainless steel (SS) polypropylene (PB), Hastelloy (HB), PVDF or Kynar (KYB). Rubber covering and other external protection systems are also available.

A hose grade is specified by using the abbreviations given. For example, Bioflex AS,PB would describe a hose with an anti-static PTFE liner and a polypropylene braid.

Note: Most of the sizes of hose and fittings listed in this brochure are available as ex-stock items and are priced accordingly. However, when certain items have not been purchased in the last 12 months, they are no longer held in stock, and are only available to Special Order. Aflex Hose will advise accordingly when enquiries are placed for these items.

Selecting the End Fittings

Corroflon is available with a range of ‘standard’ end fittings, both integral PTFE lined and non-lined

Stainless Steel End Fitting Materials

Non-Lined Spigots - are all made from Grade 316L SS

PTFE Lined Spigots - are all made from Grade 316L or Grade 316C SS

Cam and Groove Female Fittings - are made from Grade 316C SS (Body) and 316L SS (Spigot)

Swivelling Nuts and Flanges - are all made from Grade 304 SS

Ferrules - most ferrules are made from Grade 304 SS, except some are made from Grade 316L SS - consult Aflex Hose if necessary.

The equivalent specification for the different Grades of Stainless Steel are listed below:

| Grade |

BS - British Standard |

AISI - American Standard or C = Casting Grade |

EN - European Norm |

| 316L SS |

BS 316 S11 |

AISI 316 L |

EN 1.4404 |

| 316C SS |

BS 316 C16 |

CF8M |

EN 1.440 |

| 304 SS |

BS 304 S15 |

AISI 30 |

EN 1.4301 |

Conditions of Sale

Corroflon hose and hose assemblies are only supplied on the basis that the customer has read and accepted the Conditions of Sale.

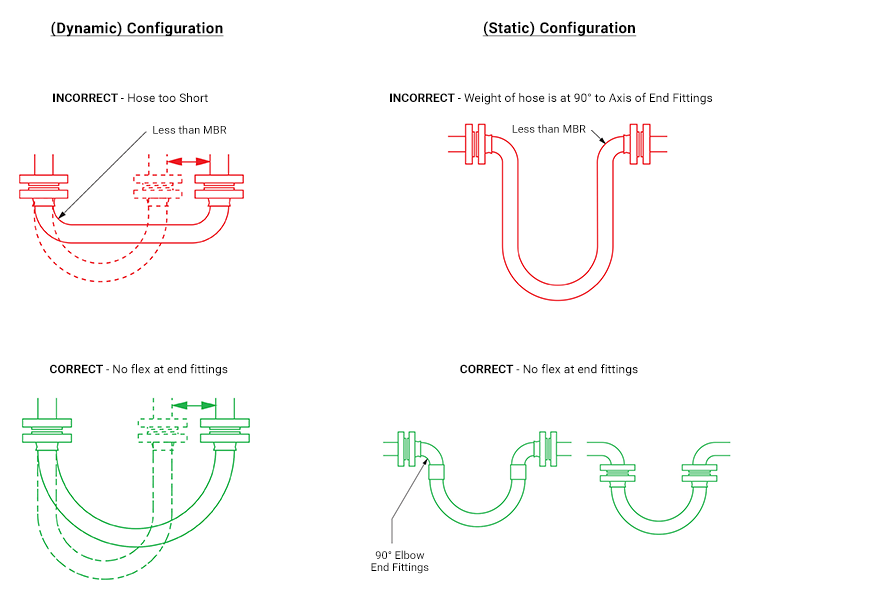

Selecting the Hose Length (see also Hose Usage Limitations)

Corroflon hose assemblies are made up to the specific lengths required. The hose length is taken as the length from the sealing face at one end of the hose to the same at the other end. The length tolerance is normally +5% / -0%. Closer tolerances are available to special order.

| Corroflon Hose Assembly Length Limitations |

| Nominal Size of Hose |

*Minimum Hose Assembly Length |

Maximum Hose Assembly Length |

| Used Straight |

Minimum at MBR |

| All Types |

TO, SS, PB, KYB |

RC |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

ft |

mtrs |

| 1/2 |

15 |

3 |

75 |

2.36 |

60 |

3.54 |

90 |

100 |

30 |

| 3/4 |

20 |

3 |

75 |

3.19 |

81 |

4.72 |

120 |

100 |

30 |

| 1 |

25 |

3 |

75 |

14.33 |

110 |

6.50 |

165 |

100 |

30 |

| 1 1/4 |

32 |

3 |

75 |

5.08 |

129 |

7.64 |

194 |

100 |

30 |

| 1 1/2 |

40 |

3 |

75 |

6.22 |

158 |

9.29 |

236 |

100 |

30 |

| 2 |

50 |

3 |

75 |

8.66 |

220 |

12.99 |

330 |

100 |

30 |

| 2 1/2 |

65 |

4 |

100 |

11.02 |

280 |

16.54 |

420 |

65 |

20 |

| 3 |

80 |

4 |

100 |

14.25 |

362 |

21.34 |

542 |

65 |

20 |

| 4 |

100 |

12 |

300 |

18.58 |

472 |

27.83 |

707 |

32 |

10 |

| 6 |

150 |

12 |

300 |

37.13 |

943 |

55.67 |

1414 |

28 |

8 |

* Listed minimum lengths are for the Corroflon Hose only, and DO NOT INCLUDE THE LENGTHS OF THE FITTINGS AT EACH END.

These must be found from the end fitting pages and added to calculate the minimum length of the hose assembly.

Used straight with fittings in line.

Only minimal vibration permitted.

Part Nos

If required, Corroflon Hose Assembly can be defined by an individual Part Number, made up of 7 entries as below:

1)

| Hose Size |

Size Part No. |

| 1/2” |

08 |

| 3/4” |

12 |

| 1” |

16 |

| 11/4” |

20 |

| 11/2” |

24 |

| 2" |

32 |

| 2 1/2" |

40 |

| 3" |

48 |

| 4" |

64 |

| 6" |

96 |

2)

| Hose Type |

Type Part No |

| Corroflon GP (Natural PTFE Liner) |

CFLN/GP |

| Corroflon AS (Antistatic PTFE Liner) |

CFLN/AS |

3)

| Braid and Cover |

| Table Only |

TO |

| Stainless Steel Braid

|

SS |

| Polypropylene Braid

|

PB |

| Hastelloy Braid

|

HB |

| Kynar (PVDF) Braid

|

KYB |

| Black EPDM Rubber Cover (on SS)

|

RC |

| Transparent Silicone Rubber (on SS)

|

SI |

| Red Fireproof EPDM Rubber (on SS)

|

FP |

4)

| External Protection Systems |

| No External Protection System

|

OO |

| S/S Wire Protection Coil |

SR |

| Rubber Anti-Scuff Rings |

SR |

| Safegard HDPE Spiral Wrap |

SG |

5)

| Length |

| The overall hose length between the sealing faces at each end is given as the Length Part No, either in decimal Metres followed by “m” or Inches followed by “in”. |

6 & 7)

Assembled End Fitting Description

* All Components in Stainless Steel

|

End Fitting Part No. |

| JIC Female |

02

|

| Fixed Male Pipe, NPT Thread |

03 |

| Fixed Male Pipe, BSPT Thread |

03/B |

| Fixed Female Pipe, NPT Thread |

06 |

| JIC-to-NPT Male Union |

08 |

| JIC-to-Female Union |

08F |

Straight Sanitary Tri Clamp, 1.984” Diameter

0.870” Exit Diameter (Standard)

1.370” Exit Diameter (Step-Up) |

-

10

10/S |

Straight Mini Sanitary Tri Clamp, 0.984” Diameter

0.370” Exit Diameter (Standard)

0.625” Exit Diameter (Step-Up) |

-

11

11/S |

| *ANSI 150# Swivelling Flange Non-Lined |

12 |

| DIN PN 10/16 Swivelling Flange Non-Lined |

12/PN |

| *ANSI 150# Swivelling Flange, PTFE Lined |

12L |

| DIN PN 10/16 Swivelling Flange, PTFE-Lined |

12/PN |

| Cam and Groove, Locking Arm Swivelling Female, Non-Lined |

16 |

| Cam and Groove Locking Arm Swivelling Female, PTFE Lined |

16L |

| Cam and Groove Male, Non-Lined |

17 |

| Cam and Groove Male, PTFE Lined |

17L |

| DIN 11851 Female, PTFE Lined |

23L |

| DIN 18851 Male, PTFE Lined |

24L |

| SMS Female, PTFE Lined |

26L |

| RJT Female, Non-Lined |

27 |

| BSPP Cone Seat Female |

33 |

| BSP Lug Nut Female |

34 |

*For flange only, Carbon Steel Zinc Plated, add “/ZP” or Epoxy coated add “/EC”

Notes:

- ELBOWS: Elbow Fittings for all types are indicated by adding “/90˚” for 90˚ elbows.

- END PROTECTION: If one of the rubber end protection systems is required, for one or both ends, please define the requirement in writing in addition to the Part Number.

TRICLAMPS: For “Hot Formed” PTFE Lined Triclamps add “/HF”

Example:

A ¾” bore Corroflon GP, RC Hose Assembly with an Antistatic PTFE Liner and an outer Safegard sleeve.

End (1) - a 3/4” ANSI 150# Swivel Flange, PTFE Lined

End (2) - a Cam and Groove Swivelling Female, PTFE Lined

Length - 4ft 6 inches

Hose Assembly Part No. = 12 - CFLN/AS - RC - SG - 54in - 12L - 16L

Additional Requirements

Any additional requirements which are not included in the Part Number must be written out in full in the Order, including any special labelling or colour coding

* Note - if one of the rubber end protection systems is required, for one or both ends, please define the requirement in writing in addition to the Part Number.

Quality Assurance & Certifications

BS EN ISO 9001:2008

Aflex products are all manufactured in accordance with BS EN ISO 9001: 2008 Quality Management Systems independently assessed and registered by The British Standards Institution (BSI).

EN 16643

Corroflon meets the requirements of EN 16643 (C), which include the electrical and electrostatic requirements of hose assemblies.

TS16949

Aflex Hose Ltd manufactures PTFE flexible hose for the automotive industry in accordance with TS16949 and is assessed and certified by The British Standards Institution (BSI).

ISO 14001:2015