|

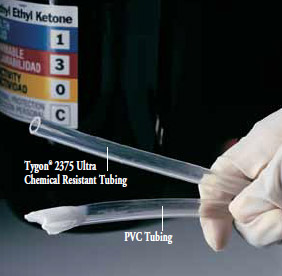

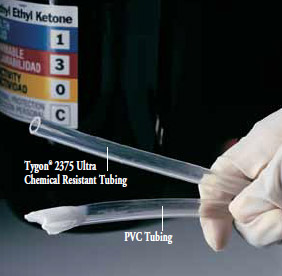

After being immersed in aggressive MEK for 16 hours (plus 4 hours drying time), Tygon®

Ultra Chemical Resistant Tubing is still clear and flexible while PVC tubing is completely degraded and rendered useless. |

Tygon®

Ultra Chemical Resistant Tubing offers an unequaled combination of chemical resistance, clarity and flexibility. Tygon®

2375 replaces 2075.

Tygon®

Ultra Chemical Resistant Tubing offers an unequaled combination of chemical resistance, clarity and flexibility. Tygon®

Ultra Chemical Resistant Tubing is virtually unaffected by acids, bases, ketones, salts and alcohols, fitting the requirements of many applications from battery acid filling to hazardous material handling. It's entirely plasticizer-free, eliminating fluid contamination and the premature embrittlement and cracking common with many flexible tubings. Its exceptionally smooth inner surface inhibits particulate buildup and reduces the potential for contamination.

Click for complete size chart

Click for complete size chart

Features/Benefits

-

Resistant to highly aggressive chemicals

- Plasticizer-free - minimizes risk of fluid contamination

- Exceptionally smooth inner surface inhibits particulate buildup

- Low sorption maintains fluid integrity

- Contains no chemicals listed in California's Prop 65

|

Typical Applications

- Fine and specialty chemical production

- Battery acid filling

- Clean and degreaser transfer systems

- X-ray processing

- Paint and solvent production

- Ink and printing fluid dispensing

- Hazardous materials handling

- Power generation sampling and drain lines

|

Tygon®

2375 Tubing Typical Physical Properties

| Property | ASTM Method | Value or Rating |

|---|

| Durometer Hardness - Shore A, 15 sec |

D2240 |

75 |

| Color | - | Clear |

| Tensile Strength - psi (MPa) (at break) |

D412 |

1900 (13.1) |

| Ultimate Elongation, % |

D412 |

850 |

| Tear Resistance - lb-f/inch (kN/m) |

D1004 |

240 (42.0) |

| Specific Gravity |

D792 | 0.9 |

| Water Absorption, % - 24 hours @ 23°

C |

D570 | < 0.01 |

| Compression Set Constant Deflection, % - @ 158°

F (70°

C) for 22 hours |

D395 - Method B |

100 |

| Brittleness by Impact Temp - °

F (°

C) |

D746 |

-103 (<-75) |

| Max Recommended Operating Temp - °

F (°

C) | - |

130 (54) |

| Low Temperature Flexibility, °

F (°

C) |

- |

-103 (-75) |

| Tensile Modulus, @ 100% Elongation, psi (MPa) | D412 |

425 (2.9) |

| Tensile Set,75 % of Ultimate Elongation, % | D412 |

300 |

| Unless

otherwise noted, all tests were conducted at room

temperature (73°

F). Values shown were determined

on 0.075" thick extruded strip or 0.075" thick

molded ASTM plaques or molded ASTM durometer

buttons. |

|