Peristaltic Pump - Sta-Pure® W.L.Gore & Associates |

||||||||||

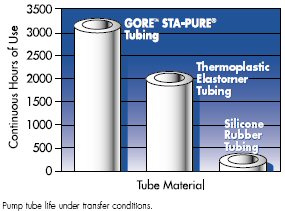

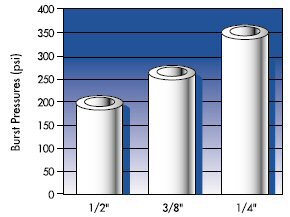

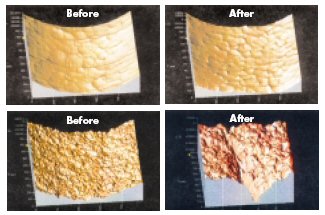

Long Life PerformanceThe exceptional longevity of the STA-PURE® W.L.Gore & Associates peristaltic pump tube is extremely beneficial for tangential flow filtration and other high-pressure applications. At a back pressure of 60 psi, this pump tube lasts over 1,000 hours with continuous use at 200 rpm. Under transfer conditions, it exhibits 18 times the life of silicone rubber tubing, and nearly twice the life of thermoplastic elastomer tubing with continuous pumping at 360 rpm. Tube rotation is eliminated, and the risk of premature tube rupture is significantly reduced. Unique structure produces highest pressure ratingThe unique composite construction of STA-PURE® W.L.Gore & Associates tubing provides superior burst resistance compared to non-reinforced silicone rubber and thermoplastic elastomer tubing. With burst strength approaching 360 psi (24 atm), the STA-PURE® W.L.Gore & Associates tube can operate at elevated pressures for filtration, transfer, and in-line steam sterilization operations. Virtually Eliminates SpallationThe exceptional toughness of the composite structure of STA-PURE® W.L.Gore & Associates tubing provides superior resistance to cracking and abrasion virtually eliminating spallation. This means the risk of filter plugging is significantly reduced without sacrificing tube life. Moreover, process streams stay cleaner, thereby reducing downstream filtration requirements. The end result: increased efficiency and throughput, along with reduced downtime. Smooth Bore Reduces ContaminationThe interior of STA-PURE® W.L.Gore & Associates tubing is three times smoother than thermoplastic elastomer tubing. During pumping, thermoplastic elastomer tubing develops grooves where the tube creases, causing rubber particles to be expelled into the process stream. The surface roughness increases from 1.6 microns to 3.6 microns in RMS roughness, whereas the STA-PURE® W.L.Gore & Associates tubing shows only a slight change in surface characteristics.

|

Our Commitment to Quality

Above all else, Carolina Components Group is committed to producing components of the highest quality.

Our customers can be assured that the products that they receive meet their stringent quality standards.

Carolina Components Group is a Member or Affiliate of: