High Purity Stainless Steel Tubing |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

To ensure the highest surface quality RathGibson goes beyond the requirements of ASTM A269 and A270 by performing the full battery of ASTM bend and deformation tests required by ASME SA249 as well as additional deformation tests developed by RathGibson. The tests, combined with specific raw material requirements, Eddy Current testing at the tube mill, 100% bore-scoping prior to mechanical polish, and tighter OD and wall tolerances allow RathGibson to provide a more consistent superior quality product.

Chemical Composition

Dimensional Tolerancesall dimensions in inches (mm)

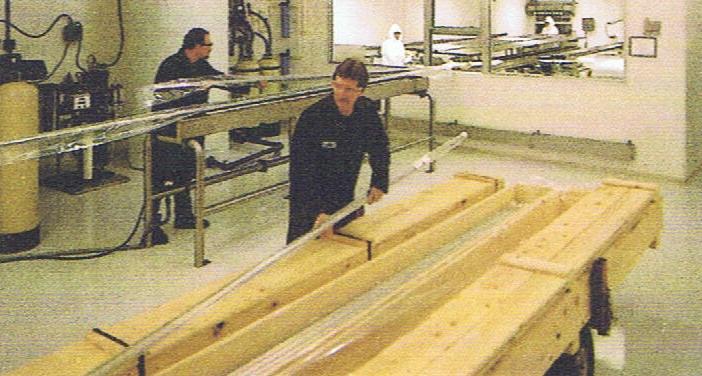

Surface finish is 20 µ-in Ra (0.5 µm) ID maximum, 30 µ-in Ra (0.8 µm) OD maximum measured per ASME/ANSI B46.1 with the profilometer reading at 90 degrees to major polishing pattern. Hydrogen bright annealed in line to 1900°F (1040°C) minimum and rapidly quenched. RathGibson A270-BPE high purity tubing ID is thermocouple cleaned per ASTM A632 S3. Tubing exceeds the requirements of ASME BPE SF1 and ASTM A270 S2. All tubing will be 100% bore-scoped and certified to 20 µ-in Ra (0.5 µm) ID maximum, 30 µ-in Ra (0.8 µm) OD maximum surface roughness measured per ASME/ANSI B46.1 with the profilometer reading at 90 degrees to major polishing pattern. As a final step in maintaining purity standards, RathGibson’s A270-BPE tubing is packaged using protective 2 mil poly sleeving along with air tight plastic end caps. The tubing is then placed in triple wall boxes for maximum protection during shipment. Other packaging is available on request.

|

Our Commitment to Quality

Above all else, Carolina Components Group is committed to producing components of the highest quality.

Our customers can be assured that the products that they receive meet their stringent quality standards.

Carolina Components Group is a Member or Affiliate of: